Page 322 - Iscar

P. 322

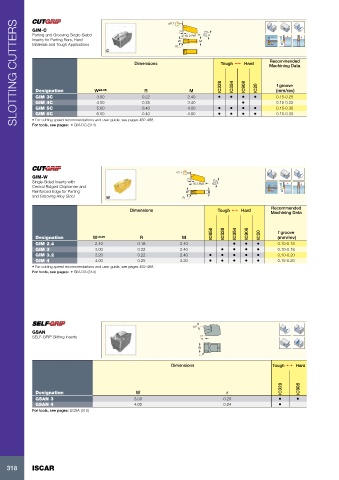

SLOTTING CUTTERS

±0.1

GIM-C 7°

Parting and Grooving Single-Sided 15.3 Ref. 5

Inserts for Parting Bars, Hard W M

Materials and Tough Applications

R

Recommended

Dimensions Tough 1 Hard

Machining Data

IC328 IC354 IC908 IC20 f groove

Designation W ±0.05 R M (mm/rev)

GIM 3C 3.00 0.22 2.40 • • • • 0.15-0.25

GIM 4C 4.00 0.25 3.40 • 0.15-0.25

GIM 5C 5.00 0.40 4.00 • • • • 0.15-0.30

GIM 6C 6.00 0.40 4.80 • • • • 0.15-0.30

• For cutting speed recommendations and user guide, see pages 462-468

For tools, see pages: • GM-DG (314)

±0.1

GIM-W 7°

Single-Sided Inserts with 15.3 Ref. 5

Central Ridged Chipformer and

Reinforced Edge for Parting W M

and Grooving Alloy Steel

R

Recommended

Dimensions Tough 1 Hard Machining Data

IC656 IC328 IC354 IC908 IC20 f groove

Designation W ±0.05 R M (mm/rev)

GIM 2.4 2.40 0.18 2.40 • • • 0.10-0.18

GIM 3 3.00 0.22 2.40 • • • • 0.10-0.18

GIM 3.2 3.20 0.22 2.40 • • • • • 0.10-0.20

GIM 4 4.00 0.25 3.20 • • • • • 0.15-0.20

• For cutting speed recommendations and user guide, see pages 462-468

For tools, see pages: • GM-DG (314)

12°

GSAN

SELF-GRIP Slitting Inserts 7°

W

r

Dimensions Tough 1 Hard

IC328 IC908

Designation W r

GSAN 3 3.00 0.20 • •

GSAN 4 4.00 0.24 •

For tools, see pages: SGSA (315)

318 ISCAR