Page 133 - CAMFIX

P. 133

l High Precision

Tools and Holders for

Quick Change

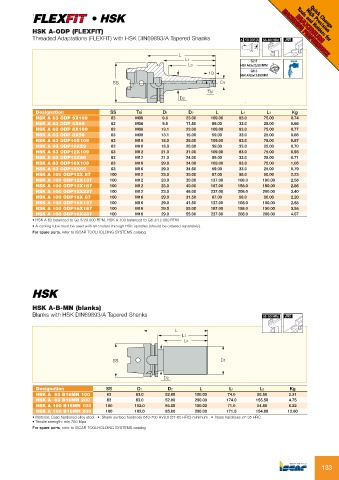

HSK A-ODP (FLEXFIT) MACHINING PERFORMANCE

Threaded Adaptations (FLEXFIT) with HSK DIN69893/A Tapered Shanks A 0.003 A 58-60 HRc √N5

MAXIMUM

L

L1 G2.5

L3 HSK A63=20,000RPM

10 G6.3

HSK A100=12,000RPM

SS D1

Tsi

D2

.

Designation SS Tsi D1 D2 L L1 L3 Kg

HSK A 63 ODP 6X109 63 M06 9.8 23.00 109.00 83.0 75.00 0.74

HSK A 63 ODP 6X59 63 M06 9.8 11.50 59.00 33.0 25.00 0.66

HSK A 63 ODP 8X109 63 M08 13.1 23.00 109.00 83.0 75.00 0.77

HSK A 63 ODP 8X59 63 M08 13.1 15.00 59.00 33.0 25.00 0.68

HSK A 63 ODP10X109 63 M10 18.0 28.00 109.00 83.0 75.00 0.87

HSK A 63 ODP10X59 63 M10 18.0 20.00 59.00 33.0 25.00 0.70

HSK A 63 ODP12X109 63 M12 21.0 31.00 109.00 83.0 75.00 0.93

HSK A 63 ODP12X59 63 M12 21.0 24.00 59.00 33.0 25.00 0.71

HSK A 63 ODP16X109 63 M16 29.0 34.00 109.00 83.0 75.00 1.05

HSK A 63 ODP16X59 63 M16 29.0 34.60 59.00 33.0 25.00 0.79

HSK A 100 ODP12X 87 100 M12 23.0 30.00 87.00 58.0 50.00 2.23

HSK A 100 ODP12X137 100 M12 23.0 30.00 137.00 108.0 100.00 2.58

HSK A 100 ODP12X187 100 M12 23.0 40.00 187.00 158.0 150.00 2.86

HSK A 100 ODP12X237 100 M12 23.0 46.00 237.00 208.0 200.00 3.40

HSK A 100 ODP16X 87 100 M16 29.0 31.50 87.00 58.0 50.00 2.20

HSK A 100 ODP16X137 100 M16 29.0 41.50 137.00 108.0 100.00 2.68

HSK A 100 ODP16X187 100 M16 29.0 55.00 187.00 158.0 150.00 3.58

HSK A 100 ODP16X237 100 M16 29.0 55.00 237.00 208.0 200.00 4.07

• HSK A 63 balanced to G2.5/20.000 RPM, HSK A 100 balanced to G6.3/12.000 RPM

• A cooling tube must be used with all coolant through HSK spindles (should be ordered separately).

For spare parts, refer to ISCAR TOOLHOLDING SYSTEMS catalog

HSK A-B-MN (blanks)

Blanks with HSK DIN69893/A Tapered Shanks 58-60 HRc √N5

L

L1

L3

SS D1

D2 .

Designation SS D1 D2 L L1 L3 Kg

HSK A 63 B16MN 100 63 63.0 52.80 100.00 74.0 55.50 2.31

HSK A 63 B16MN 200 63 63.0 52.80 200.00 174.0 155.50 4.75

HSK A 100 B16MN 100 100 102.0 85.00 100.00 71.0 54.80 6.22

HSK A 100 B16MN 200 100 102.0 85.00 200.00 171.0 154.80 12.60

• Material: Case hardened alloy steel • Shank surface hardness 640-700 HV0.5 (57-60 HRC) minimum • Nose hardness 27-35 HRC

• Tensile strength: min 760 Mpa

For spare parts, refer to ISCAR TOOLHOLDING SYSTEMS catalog

133