Page 131 - CAMFIX

P. 131

l High Precision

Tools and Holders for

Quick Change

FITBORE HSK A-EM MACHINING PERFORMANCE

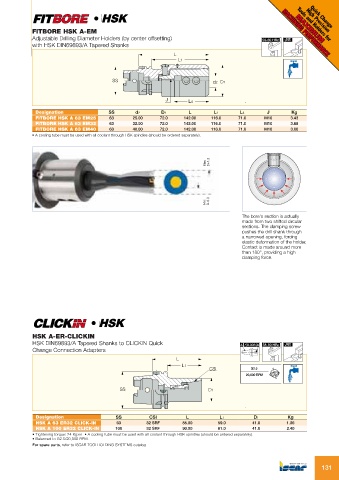

Adjustable Drilling Diameter Holders (by center offsetting) 58-60 HRc √N5

MAXIMUM

with HSK DIN69893/A Tapered Shanks

L

L1

SS d2 D1

J L4 .

Designation SS d2 D1 L L1 L4 J Kg

FITBORE HSK A 63 EM25 63 25.00 72.0 142.00 116.0 71.0 M10 3.43

FITBORE HSK A 63 EM32 63 32.00 72.0 142.00 116.0 71.0 M10 3.65

FITBORE HSK A 63 EM40 63 40.00 72.0 142.00 116.0 71.0 M10 3.00

• A cooling tube must be used with all coolant through HSK spindles (should be ordered separately).

Max: D+1.3

Min: D-0.3

The bore's section is actually

made from two shifted circular

sections. The clamping screw

pushes the drill shank through

a narrowed opening, forcing

elastic deformation of the holder.

Contact is made around more

than 180°, providing a high

clamping force.

l

HSK A-ER-CLICKIN

HSK DIN69893/A Tapered Shanks to CLICKIN Quick A 0.003 A 58-60 HRc √N5

Change Connection Adapters

L

L1

CSI G2.5

20,000 RPM

SS D1

.

Designation SS CSI L L1 D1 Kg

HSK A 63 ER32 CLICK-IN 63 32 SRF 85.00 59.0 41.0 1.06

HSK A 100 ER32 CLICK-IN 100 32 SRF 90.00 61.0 41.0 2.40

• Tightening torque: 24 Kgxm • A cooling tube must be used with all coolant through HSK spindles (should be ordered separately).

• Balanced to G2.5/20,000 RPM.

For spare parts, refer to ISCAR TOOLHOLDING SYSTEMS catalog

131