Page 129 - CAMFIX

P. 129

Quick Change

HSK A-SEM-C MACHINING PERFORMANCE

High Precision

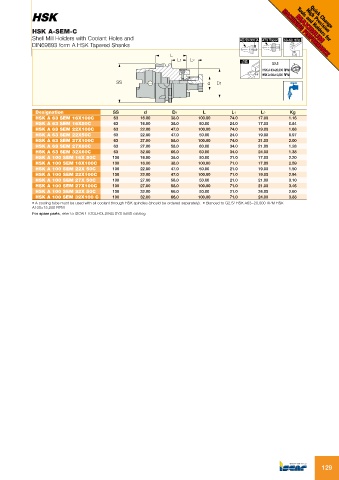

Shell Mill Holders with Coolant Holes and A 0.005 A AT3 Taper 58-60 HRc

Tools and Holders for

MAXIMUM

DIN69893 form A HSK Tapered Shanks

L

L1 L2 √N5

G2.5

HSK A 63=20,000 RPM

HSK A100=15,000 RPM

SS d D1

Designation SS d D1 L L1 L2 Kg

HSK A 63 SEM 16X100C 63 16.00 38.0 100.00 74.0 17.00 1.16

HSK A 63 SEM 16X50C 63 16.00 38.0 50.00 24.0 17.00 0.84

HSK A 63 SEM 22X100C 63 22.00 47.0 100.00 74.0 19.00 1.68

HSK A 63 SEM 22X50C 63 22.00 47.0 50.00 24.0 19.00 0.97

HSK A 63 SEM 27X100C 63 27.00 58.0 100.00 74.0 21.00 2.00

HSK A 63 SEM 27X60C 63 27.00 58.0 60.00 34.0 21.00 1.28

HSK A 63 SEM 32X60C 63 32.00 66.0 60.00 34.0 24.00 1.38

HSK A 100 SEM 16X 50C 100 16.00 38.0 50.00 21.0 17.00 2.20

HSK A 100 SEM 16X100C 100 16.00 38.0 100.00 71.0 17.00 2.59

HSK A 100 SEM 22X 50C 100 22.00 47.0 50.00 21.0 19.00 1.50

HSK A 100 SEM 22X100C 100 22.00 47.0 100.00 71.0 19.00 2.94

HSK A 100 SEM 27X 50C 100 27.00 58.0 50.00 21.0 21.00 3.10

HSK A 100 SEM 27X100C 100 27.00 58.0 100.00 71.0 21.00 3.46

HSK A 100 SEM 32X 50C 100 32.00 66.0 50.00 21.0 24.00 2.60

HSK A 100 SEM 32X100 C 100 32.00 66.0 100.00 71.0 24.00 3.88

• A cooling tube must be used with all coolant through HSK spindles (should be ordered separately). • Blanced to G2.5/ HSK A63=20,000 RPM HSK

A100=15,000 RPM

For spare parts, refer to ISCAR TOOLHOLDING SYSTEMS catalog

129