Page 452 - Hartner

P. 452

Coatings

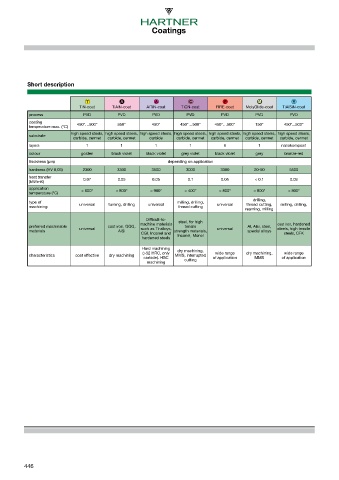

Short description

TiN-coat TiAlN-coat AlTiN-coat TiCN-coat FIRE-coat MolyGlide-coat TiAlSiN-coat

process PVD PVD PVD PVD PVD PVD PVD

coating 450°…500° 350° 450° 450°…500° 450°…500° 150° 450°...500°

temperature max. (°C)

high speed steels, high speed steels, high speed steels, high speed steels, high speed steels, high speed steels, high speed steels,

substrate

carbide, cermet carbide, cermet carbide carbide, cermet carbide, cermet carbide, cermet carbide, cermet

layers 1 1 1 1 6 1 nanokomposit

colour golden black violet black violet grey violet black violet grey bronze-red

thickness (µm) depending on application

hardness (HV 0,05) 2300 3300 3500 3000 3300 20-50 5500

heat transfer 0.07 0.05 0.05 0.1 0.05 < 0.1 0.03

(kW/mK)

application < 600° < 800° < 900° < 400° < 800° < 800° < 800°

temperature (°C)

drilling,

type of universal turning, drilling universal milling, drilling, universal thread cutting, milling, drilling,

machining thread cutting

reaming, milling

Difficult-to-

machine materials steel, for high cast iron, hardened

preferred machinable universal cast iron, GGG, such as Ti-alloys, tensile universal Al, Alsi, steel, steels, high tensile

materials AlSi strength materials, special alloys

CGI, Inconel and Inconel, Monel steels, CFK

hardened steels

Hard machining dry machining,

(>52 HRC, only wide range dry machining, wide range

characteristics cost effective dry machining MMS, interrupted

carbide). HSC cutting of application MMS of application

machining

446