Page 449 - Hartner

P. 449

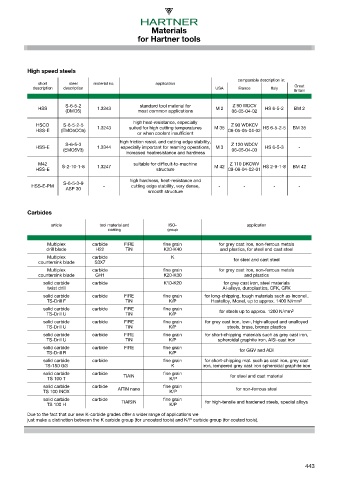

Materials

for Hartner tools

High speed steels

comparable description in:

short steel material no. application

description description USA France Italy Great

Britain

S-6-5-2 standard tool material for Z 90 WDCV

HSS (DMO5) 1.3343 most common applications M 2 06-05-04-02 HS 6-5-2 BM 2

high heat-resistance, especially

HSCO S-6-5-2-5 Z 90 WDKCV

HSS-E (EMO5CO5) 1.3243 suited for high cutting temperatures M 35 06-05-05-04-02 HS 6-5-2-5 BM 35

or when coolant insufficient

high friction resist. and cutting edge stability,

S-6-5-3 Z 120 WDCV

HSS-E 1.3344 especially important for reaming operations, M 3 HS 6-5-3 -

(EMO5V3) 06-05-04-03

increased heatresistance and hardness

M42 suitable for difficult-to-machine Z 110 DKCWV

HSS-E S-2-10-1-8 1.3247 structure M 42 09-08-04-02-01 HS 2-9-1-8 BM 42

high hardness, heat-resistance and

S-6-5-3-9

HSS-E-PM - cutting edge stability, very dense, - - - -

ASP 30

smooth structure

Carbides

article tool material and ISO- application

coating group

Multiplex carbide FIRE fine grain for grey cast iron, non-ferrous metals

drill blade H22 TiN K20-K40 and plastics, for steel and cast steel

Multiplex carbide K for steel and cast steel

countersink blade S3X7

Multiplex carbide fine grain for grey cast iron, non-ferrous metals

countersink blade GH1 K20-K30 and plastics

solid carbide carbide K10-K20 for grey cast iron, steel materials

twist drill Al-alloys, duroplastics, CFK, GFK

solid carbide carbide FIRE fine grain for long-chipping, tough materials such as Inconell,

TS-Drill F TiN K/P Hastelloy, Monel, up to approx. 1400 N/mm 2

solid carbide carbide FIRE fine grain

TS-Drill U TiN K/P for steels up to approx. 1200 N/mm 2

solid carbide carbide FIRE fine grain for grey cast iron, low-, high-alloyed and unalloyed

TS-Drill U TiN K/P steels, brass, bronze plastics

solid carbide carbide FIRE fine grain for short-chipping materials such as grey cast iron,

TS-Drill U TiN K/P spheroidal graphite iron, AlSi-cast iron

solid carbide carbide FIRE fine grain

TS-Drill R K/P for GGV and ADI

solid carbide carbide fine grain for short-chipping mat. such as cast iron, grey cast

TS-150 GG K iron, tempered grey cast iron spheroidal graphite iron

solid carbide carbide TiAlN fine grain for steel and cast material

TS 100 T K/P

solid carbide carbide AlTiN nano fine grain for non-ferrous steel

TS 100 INOX K/P

solid carbide carbide fine grain

TS 100 H TiAlSiN K/P for high-tensile and hardened steels, special alloys

Due to the fact that our new K-carbide grades offer a wider range of applications we

just make a distinction between the K carbide group (for uncoated tools) and K/P carbide group (for coated tools).

443