Page 11 - DC

P. 11

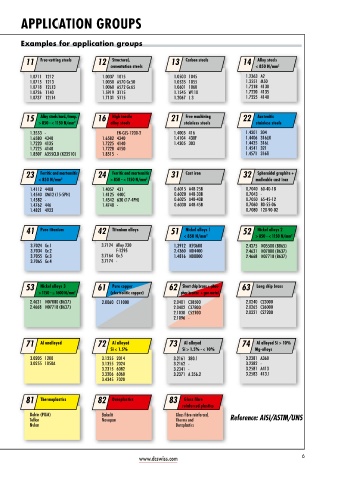

ANWENDUNGSGRUPPEN APPLICATION GROUPS

Beispiele für Anwendungsgruppen Examples for application groups

11 Automatenstahl 12 Baustahl, 13 Kohlenstoffstahl 14 Stahl legiert 11 Free-cutting steels 12 Structural, 13 Carbon steels 14 Alloy steels

Einsatzstahl < 850 N/mm 2 cementation steels < 850 N/mm 2

1.0711 9S20 1.0037 St37-2 (S235JR) 1.0503 C45 1.2363 X100CrMoV5-1 1.0711 1212 1.0037 1015 1.0503 1045 1.2363 A2

1.0715 9SMn28 1.0050 St50-2 (E295) 1.0535 C55 1.3551 80MoCrV42-16 1.0715 1213 1.0050 A570 Gr.50 1.0535 1055 1.3551 M50

1.0718 9SMnPb28 1.0060 St60-2 (E335) 1.0601 C60 1.7218 25CrMo4 1.0718 12L13 1.0060 A572 Gr.65 1.0601 1060 1.7218 4130

1.0726 35S20 1.5919 15CrNi6 1.1545 C105W1 1.7220 34CrMo4 1.0726 1140 1.5919 3115 1.1545 W110 1.7220 4135

1.0737 9SMnPb36 1.7131 16MnCr5 1.2067 102Cr6 (100Cr6) 1.7225 42CrMo4 1.0737 12L14 1.7131 5115 1.2067 L 3 1.7225 4140

15 Stahl legiert / vergütet 16 Hochfester Stahl 21 Rostfreier Stahl, 22 Austenitisch 15 Alloy steels hard./temp. 16 High tensile 21 Free machining 22 Austenitic

> 850 - < 1150 N/mm 2 geschwefelt > 850 - < 1150 N/mm 2 alloy steels stainless steels stainless steels

1.3553 X82WMoCrV6-5-4 EN-GJS-1200-2 1.4005 X12CrS13 1.4301 X5CrNi18-10 1.3553 - EN-GJS-1200-2 1.4005 416 1.4301 304

1.6580 30CrNiMo8 1.6582 34CrNiMo6v 1.4104 X14CrMoS17 1.4406 X2CrNiMoN17-12-2 1.6580 4340 1.6582 4340 1.4104 430F 1.4406 316LN

1.7220 34CrMo4 1.7225 42CrMo4v 1.4305 X10CrNiS18-9 1.4435 X2CrNiMo18-14-3 1.7220 4135 1.7225 4140 1.4305 303 1.4435 316L

1.7225 42CrMo4 1.7228 50CrMo4v 1.4541 X6CrNiTi18-10 1.7225 4140 1.7228 4150 1.4541 321

1.8507 34CrAIMo5 1.8515 31CrMo12v 1.4571 X6CrNiMoTi17-12-2 1.8507 A355CLD (K23510) 1.8515 - 1.4571 316Ti

23 Ferritisch, martensitisch 24 Ferritisch, martensitisch 31 Grauguss 32 Kugelgraphitguss, 23 Ferritic and martensitic 24 Ferritic and martensitic 31 Cast iron 32 Spheroidal graphite +

< 850 N/mm 2 > 850 - < 1150 N/mm 2 Temperguss < 850 N/mm 2 > 850 - < 1150 N/mm 2 malleable cast iron

1.4112 X90CrMoV18 1.4057 X17CrNi17-2 0.6015 GG15 0.7040 GGG40 1.4112 440B 1.4057 431 0.6015 A48-25B 0.7040 60-40-18

1.4540 X4CrNiCuNb16-4 1.4125 X105CrMo17 0.6020 GG20 0.7043 GGG40.3 1.4540 XM12 (15-5PH) 1.4125 440C 0.6020 A48-30B 0.7043 -

1.4582 X4CrNiMoNb25-7 1.4542 X5CrNiCuNb16-4 0.6025 GG25 0.7050 GGG50 1.4582 - 1.4542 630 (17-4PH) 0.6025 A48-40B 0.7050 65-45-12

1.4762 X10CrAI24 1.4548 X5CrNiCuNb17-4-4 0.6030 GG30 0.7060 GGG60 1.4762 446 1.4748 - 0.6030 A48-45B 0.7060 80-55-06

1.4922 X20CrMo11-1 1.4748 X85CrMoV18-2 0.7080 GGG80 1.4821 4922 0.7080 120-90-02

41 Reintitan 42 Titanlegierung 51 Nickellegierung 1 52 Nickellegierung 2 41 Pure titanium 42 Titanium alloys 51 Nickel alloys 1 52 Nickel alloys 2

< 850 N/mm 2 > 850 - < 1150 N/mm 2 < 850 N/mm 2 > 850 - < 1150 N/mm 2

3.7024 Grad1 3.7124 TiCu2.5 1.3912 Ni36 (Invar) 2.4375 NiCu30Al (MonelK500) 3.7024 Gr.1 3.7124 Alloy 230 1.3912 K93600 2.4375 N05500 (B865)

3.7034 Grad2 Ti6Al7Nb 2.4360 NiCu30Fe (Monel 400) 2.4631 NiCr20TiAI 3.7034 Gr.2 F-1295 2.4360 N04400 2.4631 N07080 (B637)

3.7055 Grad3 3.7164 TiAl6V4 (Grad5) 2.4816 NiCr15Fe (Inconel 600) (Nimonic 80) 3.7055 Gr.3 3.7164 Gr.5 1.4816 N08800 2.4668 N07718 (B637)

3.7065 Grad4 3.7174 TiAl6V6Sn2 1.4876 X10NiCrAITi32-20 2.4668 NiCr19NbMo 3.7065 Gr.4 3.7174 -

(Inconel718)

53 Nickellegierung 3 61 Reinkupfer 62 Messing, Bronze, 63 Messing 53 Nickel alloys 3 61 Pure copper 62 Short chip brass + phos- 63 Long chip brass

> 1150 - ≤ 1600 N/mm 2 (Elektrolytkupfer) Rotguss (kurzspanend) (langspanend) > 1150 - ≤ 1600 N/mm 2 (electrolitic copper) phor bronze + gun metal

2.4631 NiCr20TiAI 2.0060 E-Cu57 (E-Cu) 2.0401 CuZn39Pb3 (Ms58) 2.0240 CuZn15 (Ms85) 2.4631 N07080 (B637) 2.0060 C11000 2.0401 C38500 2.0240 C23000

(Nimonic80) 2.0402 CuZn40Pb2 (Ms58) 2.0265 CuZn30 (Ms70) 2.4668 N07718 (B637) 2.0402 C37800 2.0265 C26000

2.4668 NiCr19NbMo 2.1030 CuSn8 (Bz) 2.0321 CuZn37 (Ms63) 2.1030 C52100 2.0321 C27200

(Inconel718) 2.1096 G-CuSn5ZnPb 2.1096 -

71 Al unlegiert 72 Al legiert 73 Al legiert 74 Al legiert Si > 10% 71 Al unalloyed 72 Al alloyed 73 Al alloyed 74 Al alloyed Si > 10%

Si < 1.5% Si > 1.5% - < 10% Mg-Legierung Si < 1.5% Si > 1.5% - < 10% Mg-alloys

3.0205 Al99 3.1255 AICuSiMn 3.2161 G-AISi8Cu3 3.2381 G-AISi10Mg 3.0205 1200 3.1255 2014 3.2161 380.1 3.2381 A360

3.0255 Al99.5 3.1355 AICuMg2 3.2162 GD-AISi8Cu3 3.2382 GD-AISi10Mg 3.0255 1050A 3.1355 2024 3.2162 - 3.2382 -

3.2315 AIMgSi1 3.2341 G-AISi5Mg 3.2581 G-AISi12 3.2315 6082 3.2341 - 3.2581 A413

3.3206 AIMgSi0.5 3.2371 G-AISi7Mg 3.2583 G-ALSi12 (Cu) 3.3206 6060 3.2371 A 356.2 3.2583 413.1

3.4345 AIZnMgCu0.5 3.4345 7020

81 Thermoplaste 82 Duroplaste 83 Faserverstärkte 81 Thermoplastics 82 Duroplastics 83 Glass fibre

Kunststoffe reinforced plastics

Delrin (POM) Bakelit Glasfaserverstärkte Referenz: DIN Delrin (POM) Bakelit Glass fibre reinforced, Reference: AISI/ASTM/UNS

Teflon Novopan Thermo- und Duroplaste Teflon Novopan Thermo and

Nylon Nylon Duroplastics

6

THREADING

TECHNOLOGY