Page 955 - Iscar

P. 955

USER GUIDE

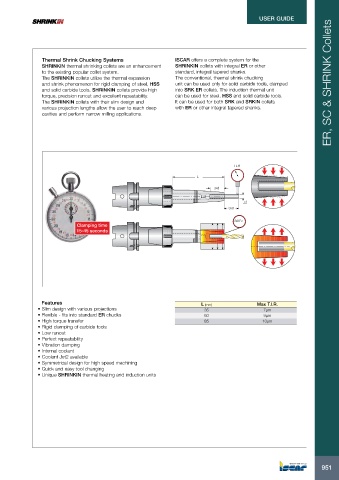

Thermal Shrink Chucking Systems ISCAR offers a complete system for the

SHRINKIN thermal shrinking collets are an enhancement SHRINKIN collets with integral ER or other

to the existing popular collet system. standard, integral tapered shanks.

The SHRINKIN collets utilize the thermal expansion The conventional, thermal shrink chucking

and shrink phenomenon for rigid clamping of steel, HSS unit can be used only for solid carbide tools, clamped ER, SC & SHRINK Collets

and solid carbide tools. SHRINKIN collets provide high into SRK ER collets. The induction thermal unit

torque, precision runout and excellent repeatability. can be used for steel, HSS and solid carbide tools.

The SHRINKIN collets with their slim design and It can be used for both SRK and SRKIN collets

various projection lengths allow the user to reach deep with ER or other integral tapered shanks.

cavities and perform narrow milling applications.

T.I.R

L

3xd

d

3xd

300˚ c

Clamping time

15-45 seconds

Features L (mm) Max T.I.R.

• Slim design with various projections 35 7µm

• Flexible - fits into standard ER chucks 60 9µm

• High torque transfer 85 10µm

• Rigid clamping of carbide tools

• Low runout

• Perfect repeatability

• Vibration damping

• Internal coolant

• Coolant Jet2 available

• Symmetrical design for high speed machining

• Quick and easy tool changing

• Unique SHRINKIN thermal heating and induction units

951