Page 950 - Iscar

P. 950

USER GUIDE

ER, SC & SHRINK Collets

ER - Top Clamping Nut for DIN 6499 Collets

Description

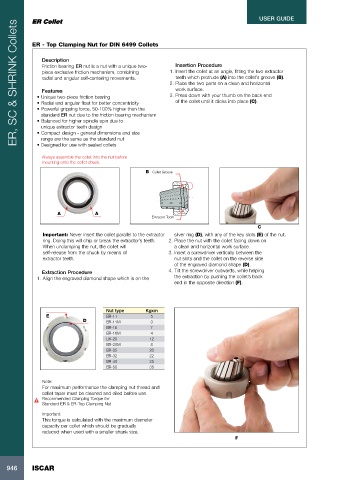

Friction bearing ER nut is a nut with a unique two- Insertion Procedure

piece exclusive friction mechanism, combining 1. Insert the collet at an angle, fitting the two extractor

radial and angular self-centering movements. teeth which protrude (A) into the collet’s groove (B).

2. Place the two parts on a clean and horizontal

Features work surface.

• Unique two-piece friction bearing 3. Press down with your thumb on the back end

• Radial and angular float for better concentricity of the collet until it clicks into place (C).

• Powerful gripping force, 50-100% higher than the

standard ER nut due to the friction bearing mechanism

• Balanced for higher spindle spin due to

unique extractor teeth design

• Compact design - general dimensions and size

range are the same as the standard nut

• Designed for use with sealed collets

Always assemble the collet into the nut before

mounting onto the collet chuck.

B Collet Groove

A A

Extractor Teeth

C

Important: Never insert the collet parallel to the extractor silver ring (D), with any of the key slots (E) of the nut.

ring. Doing this will chip or break the extractor’s teeth. 2. Place the nut with the collet facing down on

When unclamping the nut, the collet will a clean and horizontal work surface.

self-release from the chuck by means of 3. Insert a screwdriver vertically between the

extractor teeth. nut slots and the collet on the reverse side

of the engraved diamond shape (D).

Extraction Procedure 4. Tilt the screwdriver outwards, while helping

1. Align the engraved diamond shape which is on the the extraction by pushing the collet’s back

end in the opposite direction (F).

Nut type Kgxm

E ER-11 5

D ER-11M 3

ER-16 7

ER-16M 4

ER-20 12

ER-20M 8

ER-25 20

ER-32 22

ER-40 25

ER-50 35

Note:

For maximum performance the clamping nut thread and

collet taper must be cleaned and oiled before use.

Recommended Clamping Torque for

Standard ER & ER-Top Clamping Nut

Important:

This torque is calculated with the maximum diameter

capacity per collet which should be gradually

reduced when used with a smaller shank size.

F

946 ISCAR