Page 946 - Iscar

P. 946

apping & Reaming Devices

SS S 58-60 HRc

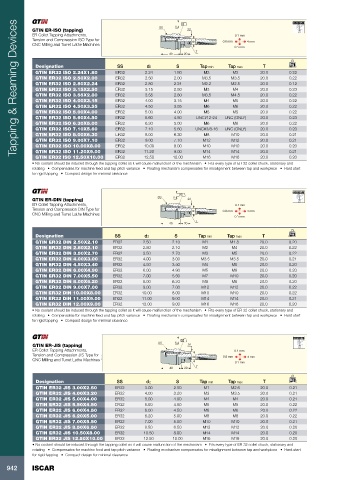

GTIN ER-ISO (tapping) 22

ER Collet Tapping Attachments, 0.1 mm

Tension and Compression ISO Type for d2 0.8 mm 4 mm

CNC Milling and Turret Lathe Machines

0.1 mm

T

40 20

Designation SS d2 S Tap min Tap max T kg

GTIN ER32 ISO 2.24X1.80 ER32 2.24 1.80 M3 M3 20.0 0.22

GTIN ER32 ISO 2.50X2.00 ER32 2.50 2.00 M3.5 M3.5 20.0 0.22

GTIN ER32 ISO 2.80X2.24 ER32 2.80 2.24 M2.2 M2.5 20.0 0.12

GTIN ER32 ISO 3.15X2.50 ER32 3.15 2.50 M3 M4 20.0 0.23

GTIN ER32 ISO 3.55X2.80 ER32 3.55 2.80 M3.5 M4.5 20.0 0.22

GTIN ER32 ISO 4.00X3.15 ER32 4.00 3.15 M4 M5 20.0 0.22

GTIN ER32 ISO 4.50X3.55 ER32 4.50 3.55 M6 M6 20.0 0.22

GTIN ER32 ISO 5.00X4.00 ER32 5.00 4.00 M5 M5 20.0 0.22

GTIN ER32 ISO 5.60X4.50 ER32 5.60 4.50 UNC#12-24 UNC (ONLY) 20.0 0.23

GTIN ER32 ISO 6.30X5.00 ER32 6.30 5.00 M6 M8 20.0 0.22

GTIN ER32 ISO 7.10X5.60 ER32 7.10 5.60 UNC#3/8-16 UNC (ONLY) 20.0 0.20

GTIN ER32 ISO 8.00X6.30 ER32 8.00 6.30 M8 M10 20.0 0.21

GTIN ER32 ISO 9.00X7.10 ER32 9.00 7.10 M12 M12 20.0 0.21

GTIN ER32 ISO 10.00X8.00 ER32 10.00 8.00 M10 M10 20.0 0.20

T GTIN ER32 ISO 11.20X9.00 ER32 11.20 9.00 M14 M14 20.0 0.21

GTIN ER32 ISO 12.50X10.00 ER32 12.50 10.00 M16 M16 20.0 0.20

• No coolant should be induced through the tapping collet as it will cause malfunction of the mechanism • Fits every type of ER 32 collet chuck, stationary and

rotating • Compensates for machine feed and tap pitch variance • Floating mechanism compensates for misalignment between tap and workpiece • Hard start

for rigid tapping • Compact design for minimal clearance

58-60 HRc

GTIN ER-DIN (tapping) SS S 22

ER Collet Tapping Attachments, 0.1 mm

Tension and Compression DIN Type for d2 0.8 mm 4 mm

CNC Milling and Turret Lathe Machines

0.1 mm

T

40 20

Designation SS d2 S Tap min Tap max T kg

GTIN ER32 DIN 2.50X2.10 ER32 2.50 2.10 M1 M1.8 20.0 0.20

GTIN ER32 DIN 2.80X2.10 ER32 2.80 2.10 M2 M4 20.0 0.22

GTIN ER32 DIN 3.50X2.70 ER32 3.50 2.70 M3 M5 20.0 0.22

GTIN ER32 DIN 4.00X3.00 ER32 4.00 3.00 M3.5 M3.5 20.0 0.21

GTIN ER32 DIN 4.50X3.40 ER32 4.50 3.40 M4 M6 20.0 0.20

GTIN ER32 DIN 6.00X4.90 ER32 6.00 4.90 M5 M8 20.0 0.20

GTIN ER32 DIN 7.00X5.50 ER32 7.00 5.50 M7 M10 20.0 0.20

GTIN ER32 DIN 8.00X6.20 ER32 8.00 6.20 M8 M8 20.0 0.20

GTIN ER32 DIN 9.00X7.00 ER32 9.00 7.00 M12 M12 20.0 0.22

GTIN ER32 DIN 10.00X8.00 ER32 10.00 8.00 M10 M10 20.0 0.22

GTIN ER32 DIN 11.00X9.00 ER32 11.00 9.00 M14 M14 20.0 0.21

GTIN ER32 DIN 12.00X9.00 ER32 12.00 9.00 M16 M16 20.0 0.20

• No coolant should be induced through the tapping collet as it will cause malfunction of the mechanism • Fits every type of ER 32 collet chuck, stationary and

rotating • Compensates for machine feed and tap pitch variance • Floating mechanism compensates for misalignment between tap and workpiece • Hard start

for rigid tapping • Compact design for minimal clearance

58-60 HRc

GTIN ER-JIS (tapping) SS S 22

ER Collet Tapping Attachments, 0.1 mm

Tension and Compression JIS Type for d2 0.8 mm 4 mm

CNC Milling and Turret Lathe Machines

0.1 mm

40 20 T

Designation SS d2 S Tap min Tap max T kg

GTIN ER32 JIS 3.00X2.50 ER32 3.00 2.50 M1 M2.6 20.0 0.21

GTIN ER32 JIS 4.00X3.20 ER32 4.00 3.20 M3 M3.5 20.0 0.21

GTIN ER32 JIS 5.00X4.00 ER32 5.00 4.00 M4 M4 20.0 0.21

GTIN ER32 JIS 5.50X4.50 ER32 5.50 4.50 M5 M5 20.0 0.22

GTIN ER32 JIS 6.00X4.50 ER32 6.00 4.50 M6 M6 20.0 0.22

GTIN ER32 JIS 6.20X5.00 ER32 6.20 5.00 M8 M8 20.0 0.22

GTIN ER32 JIS 7.00X5.50 ER32 7.00 5.50 M10 M10 20.0 0.21

GTIN ER32 JIS 8.50X6.50 ER32 8.50 6.50 M12 M12 20.0 0.20

GTIN ER32 JIS 10.50X8.00 ER32 10.50 8.00 M14 M14 20.0 0.20

GTIN ER32 JIS 12.50X10.00 ER32 12.50 10.00 M16 M16 20.0 0.20

• No coolant should be induced through the tapping collet as it will cause malfunction of the mechanism • Fits every type of ER 32 collet chuck, stationary and

rotating • Compensates for machine feed and tap pitch variance • Floating mechanism compensates for misalignment between tap and workpiece • Hard start

for rigid tapping • Compact design for minimal clearance

942 ISCAR