Page 734 - Iscar

P. 734

USER GUIDE

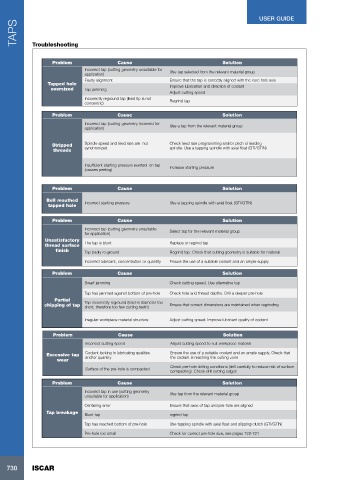

TAPS Troubleshooting

Problem Cause Solution

Incorrect tap (cutting geometry unsuitable for Use tap selected from the relevant material group

application)

Faulty alignment Ensure that the tap is correctly aligned with the core hole axis

Tapped hole

oversized Tap jamming Improve lubrication and direction of coolant

Adjust cutting speed

Incorrectly reground tap (lead tip is not Regrind tap

concentric)

Problem Cause Solution

Incorrect tap (cutting geometry incorrect for Use a tap from the relevant material group

application)

Stripped Spindle speed and feed rate are not Check feed rate programming and/or pitch of leading

threads synchronized spindle. Use a tapping spindle with axial float (GTI/GTIN)

Insufficient starting pressure exerted on tap Increase starting pressure

(causes peeling)

Problem Cause Solution

Bell mouthed

tapped hole Incorrect starting pressure Use a tapping spindle with axial float (GTI/GTIN)

Problem Cause Solution

Incorrect tap (cutting geometry unsuitable Select tap for the relevant material group

for application)

Unsatisfactory

thread surface The tap is blunt Replace or regrind tap

finish Tap badly re-ground Regrind tap. Check that cutting geometry is suitable for material

Incorrect lubricant, concentration or quantity Ensure the use of a suitable coolant and an ample supply

Problem Cause Solution

Swarf jamming Check cutting speed. Use alternative tap

Tap has jammed against bottom of pre-hole Check hole and thread depths. Drill a deeper pre-hole

Partial

chipping of tap Tap incorrectly reground (lead-in diameter too Ensure that correct dimensions are maintained when regrinding

short, therefore too few cutting teeth)

Irregular workpiece material structure Adjust cutting speed. Improve lubricant quality of coolant

Problem Cause Solution

Incorrect cutting speed Adjust cutting speed to suit workpiece material

Excessive tap Coolant lacking in lubricating qualities Ensure the use of a suitable coolant and an ample supply. Check that

wear and/or quantity the coolant is reaching the cutting zone

Check pre-hole drilling conditions (drill carefully to reduce risk of surface

Surface of the pre-hole is compacted

compacting). Check drill cutting edges

Problem Cause Solution

Incorrect tap in use (cutting geometry Use tap from the relevant material group

unsuitable for application)

Centering error Ensure that axes of tap and pre-hole are aligned

Tap breakage

Blunt tap regrind tap

Tap has reached bottom of pre-hole Use tapping spindle with axial float and slipping clutch (GTI/GTIN)

Pre-hole too small Check for correct pre-hole size, see pages 720-721

ISCAR

730 ISCAR

730