Page 732 - Iscar

P. 732

USER GUIDE

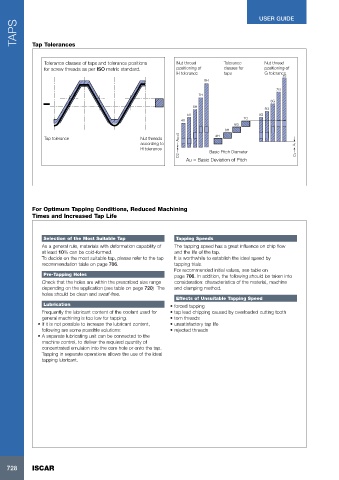

TAPS Tap Tolerances

Tolerance classes of taps and tolerance positions Nut thread Tolerance Nut thread

for screw threads as per ISO metric standard. positioning of classes for positioning of

H tolerance taps G tolerance

8H

7G

7H

6G

6H

5G

5H 4G

7G

4H

6G

6H

=0 4H

Tap tolerance Nut threads Au

according to Au

H tolerance

Basic Pitch Diameter

D2 D2

Au = Basic Deviation of Pitch

For Optimum Tapping Conditions, Reduced Machining

Times and Increased Tap Life

Selection of the Most Suitable Tap Tapping Speeds

As a general rule, materials with deformation capability of The tapping speed has a great influence on chip flow

at least 10% can be cold-formed. and the life of the tap.

To decide on the most suitable tap, please refer to the tap It is worthwhile to establish the ideal speed by

recommendation table on page 706. tapping trials.

For recommended initial values, see table on

Pre-Tapping Holes page 706. In addition, the following should be taken into

Check that the holes are within the prescribed size range consideration: characteristics of the material, machine

depending on the application (see table on page 720) The and clamping method.

holes should be clean and swarf-free.

Effects of Unsuitable Tapping Speed

Lubrication • forced tapping

Frequently the lubricant content of the coolant used for • tap lead chipping caused by overloaded cutting tooth

general machining is too low for tapping. • torn threads

• If it is not possible to increase the lubricant content, • unsatisfactory tap life

following are some possible solutions: • rejected threads

• A separate Iubricating unit can be connected to the

machine control, to deliver the required quantity of

concentrated emulsion into the core hole or onto the tap.

Tapping in separate operations allows the use of the ideal

tapping lubricant.

ISCAR

728 ISCAR

728