Page 704 - Iscar

P. 704

USER GUIDE

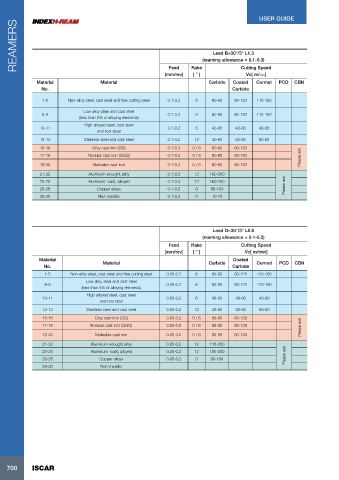

REAMERS (reaming allowance = 0.1-0.3)

Lead B=30°/3° L1.3

Feed

[mm/rev] Rake Cutting Speed

[ ° ]

Vc[ m/min]

Material Material Carbide Coated Cermet PCD CBN

No. Carbide

1-5 Non-alloy steel, cast steel and free cutting steel 0.1-0.3 6 60-80 80-120 110-160

Low alloy steel and cast steel

6-9 0.1-0.3 6 60-80 80-120 110-160

(less than 5% of alloying elements)

High alloyed steel, cast steel

10-11 0.1-0.3 6 40-60 40-80 40-80

and tool steel

12-13 Stainless steel and cast steel 0.1-0.2 12 40-60 60-80 60-80

15-16 Grey cast iron (GG) 0.1-0.3 0 / 6 60-80 80-120

17-18 Nodular cast iron (GGG) 0.1-0.3 0 / 6 60-80 80-120 Please ask

19-20 Malleable cast iron 0.1-0.3 0 / 6 60-80 80-120

21-22 Aluminum wrought alloy 0.1-0.3 12 160-200

23-25 Aluminum -cast, alloyed 0.1-0.3 12 160-200 Please ask

26-28 Copper alloys 0.1-0.2 0 80-100

29-30 Non-metallic 0.1-0.3 0 10-70

Lead D=30°/3° L0.6

(reaming allowance = 0.1-0.2)

Feed Rake Cutting Speed

[mm/rev] [ ° ] Vc[ m/min]

Material Material Carbide Coated Cermet PCD CBN

No. Carbide

1-5 Non-alloy steel, cast steel and free cutting steel 0.05-0.2 6 60-80 80-120 110-160

Low alloy steel and cast steel

6-9 0.05-0.2 6 60-80 80-120 110-160

(less than 5% of alloying elements)

High alloyed steel, cast steel

10-11 0.05-0.2 6 40-60 40-80 40-80

and tool steel

12-13 Stainless steel and cast steel 0.05-0.2 12 40-60 60-80 60-80

15-16 Grey cast iron (GG) 0.05-0.2 0 / 6 60-80 80-120

17-18 Nodular cast iron (GGG) 0.05-0.2 0 / 6 60-80 80-120 Please ask

19-20 Malleable cast iron 0.05-0.2 0 / 6 60-80 80-120

21-22 Aluminum wrought alloy 0.05-0.2 12 110-200

23-25 Aluminum -cast, alloyed 0.05-0.2 12 180-200 Please ask

26-28 Copper alloys 0.05-0.2 0 80-100

29-30 Non-metallic

ISCAR

700 ISCAR

700