Page 700 - Iscar

P. 700

USER GUIDE

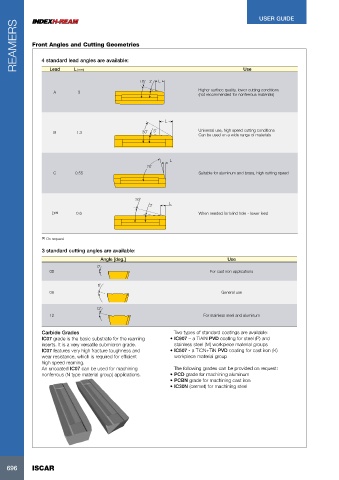

REAMERS Front Angles and Cutting Geometries

4 standard lead angles are available:

Lead

L [mm]

15˚ 3˚ L Use

Higher surface quality, lower cutting conditions

A 3

(not recommended for nonferrous materials)

L

B 1.3 30˚ 3˚ Universal use, high speed cutting conditions

Can be used on a wide range of materials

L

75˚

C 0.55 Suitable for aluminum and brass, high cutting speed

30˚

L

3˚

D (1) 0.6 When needed for blind hole - lower feed

(1) On request

3 standard cutting angles are available:

Angle [deg.] Use

0˚

00 For cast iron applications

6˚

06 General use

12˚

12 For stainless steel and aluminum

Carbide Grades Two types of standard coatings are available:

IC07 grade is the basic substrate for the reaming • IC907 – a TiAlN PVD coating for steel (P) and

inserts. It is a very versatile submicron grade. stainless steel (M) workpiece material groups

IC07 features very high fracture toughness and • IC507 - a TiCN+TiN PVD coating for cast iron (K)

wear resistance, which is required for efficient workpiece material group

high speed reaming.

An uncoated IC07 can be used for machining The following grades can be provided on request:

nonferrous (N type material group) applications. • PCD grade for machining aluminum

• PCBN grade for machining cast iron

• IC30N (cermet) for machining steel

ISCAR

696 ISCAR

696