Page 52 - Iscar

P. 52

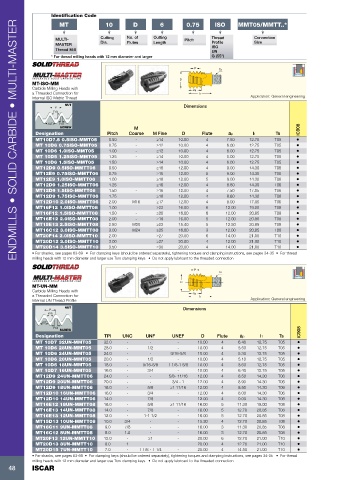

Identification Code

ENDMILLS • SOLID CARBIDE • MULTI-MASTER

MT 10 D 6 0.75 ISO MMT05/MMTT..*

MULTI- Cutting No. of Cutting Pitch Thread Connection

MASTER Dia. Flutes Length Profile Size

Thread Mill ISO

UN

* For thread milling heads with 12 mm diameter and larger G (55°)

P

Ts

D

MT-ISO-MM

Carbide Milling Heads with ap

a Threaded Connection for l1

Internal ISO Metric Thread Application: General engineering

NUT

P Dimensions

P/4

60˚ P/8

SCREW M IC908

Designation Pitch Coarse M Fine D Flute ap l1 Ts

MT10D7.5 0.5ISO-MMT05 0.50 - ≥14 10.00 4 7.50 12.75 T05 •

MT 10D6 0.75ISO-MMT05 0.75 - ≥12 10.00 4 6.00 12.75 T05 •

MT 10D6 1.0ISO-MMT05 1.00 - ≥12 10.00 4 6.00 12.75 T05 •

MT 10D5 1.25ISO-MMT05 1.25 - ≥14 10.00 4 5.00 12.75 T05 •

MT 10D6 1.5ISO-MMT05 1.50 - ≥14 10.00 4 6.00 12.75 T05 •

MT12D9 0.5ISO-MMTT06 0.50 ≥16 12.00 4 9.00 14.30 T06 •

MT12E9 0.75ISO-MMTT06 0.75 ≥16 12.00 5 9.00 14.30 T06 •

MT12E9 1.0ISO-MMTT06 1.00 ≥16 12.00 5 9.00 14.30 T06 •

MT12D9 1.25ISO-MMTT06 1.25 ≥16 12.00 4 8.80 14.30 T06 •

MT12D9 1.5ISO-MMTT06 1.50 - ≥16 12.00 4 7.50 17.05 T06 •

MT12D9 1.75ISO-MMTT06 1.75 ≥16 12.00 4 8.80 14.30 T06 •

MT12D10 2.0ISO-MMTT06 2.00 M16 ≥17 12.00 4 8.00 17.05 T06 •

MT16F12 1.0ISO-MMTT08 1.00 ≥22 16.00 6 12.00 19.00 T08 •

MT16F12 1.5ISO-MMTT08 1.50 - ≥20 16.00 6 12.00 20.85 T08 •

MT16E12 2.0ISO-MMTT08 2.00 - ≥19 16.00 5 12.00 20.85 T08 •

MT15E13 2.5ISO-MMTT08 2.50 M20 ≥22 15.40 5 12.50 20.85 T08 •

MT16C12 3.0ISO-MMTT08 3.00 M24 ≥25 16.00 3 12.00 20.85 T08 •

MT20F14 2.0ISO-MMTT10 2.00 ≥27 20.00 6 14.00 21.00 T10 •

MT20D12 3.0ISO-MMTT10 3.00 ≥27 20.00 4 12.00 21.00 T10 •

MT20D14 3.5ISO-MMTT10 3.50 ≥30 20.00 4 14.00 21.00 T10 •

• For shanks, see pages 63-69 • For clamping keys (should be ordered separately), tightening torques and clamping instructions, see pages 34-35 • For thread

milling heads with 12 mm diameter and larger use Torx clamping keys • Do not apply lubricant to the threaded connection

P

Ts

D

MT-UN-MM

Carbide Milling Heads with

a Threaded Connection for ap l1

Internal UN Thread Profile Application: General engineering

NUT

P Dimensions

P/8

60˚

P/4

SCREW IC908

Designation TPI UNC UNF UNEF D Flute ap l1 Ts

MT 10D7 32UN-MMT05 32.0 - - - 10.00 4 6.40 12.75 T05 •

MT 10D6 28UN-MMT05 28.0 - 1/2 - 10.00 4 5.50 12.75 T05 •

MT 10D6 24UN-MMT05 24.0 - - 9/16-5/8 10.00 4 5.30 12.75 T05 •

MT 10D6 20UN-MMT05 20.0 - 1/2 - 10.00 4 5.10 12.75 T05 •

MT 10D5 18UN-MMT05 18.0 - 9/16-5/8 1 1/8-1 5/8 10.00 4 5.60 12.75 T05 •

MT 10D7 16UN-MMT05 16.0 - 3/4 - 10.00 4 6.40 12.75 T05 •

MT12D9 24UN-MMTT06 24.0 - - 5/8- 11/16 12.00 4 8.50 14.30 T06 •

MT12D9 20UN-MMTT06 20.0 - - 3/4 - 1 12.00 4 8.90 14.30 T06 •

MT12D9 18UN-MMTT06 18.0 - 5/8 ≥1 11/16 12.00 4 8.50 14.30 T06 •

MT12D10 16UN-MMTT06 16.0 - 3/4 - 12.00 4 8.00 14.30 T06 •

MT12D10 14UN-MMTT06 14.0 - 7/8 12.00 4 0.00 14.30 T06 •

MT16E12 18UN-MMTT08 18.0 - 5/8 ≥1 11/16 16.00 5 11.30 19.00 T08 •

MT16E13 14UN-MMTT08 14.0 - 7/8 - 16.00 5 12.70 20.85 T08 •

MT16E13 12UN-MMTT08 12.0 - 1-1 1/2 - 16.00 5 12.70 20.85 T08 •

MT15D13 10UN-MMTT08 10.0 3/4 - - 15.30 4 12.70 20.85 T08 •

MT16C11 9UN-MMTT08 9.0 7/8 - - 16.00 3 11.30 20.85 T08 •

MT16C12 8UN-MMTT08 8.0 1.0 - - 16.00 3 12.70 20.85 T08 •

MT20F13 12UN-MMTT10 12.0 - ≥1 - 20.00 6 12.70 21.00 T10 •

MT20D13 8UN-MMTT10 8.0 1 20.00 4 12.70 21.00 T10 •

MT20D15 7UN-MMTT10 7.0 - 1 1/8 - 1 1/4 - 20.00 4 14.50 21.00 T10 •

• For shanks, see pages 63-69 • For clamping keys (should be ordered separately), tightening torques and clamping instructions, see pages 34-35 • For thread

milling heads with 12 mm diameter and larger use Torx clamping keys • Do not apply lubricant to the threaded connection

48 ISCAR