Page 53 - Iscar

P. 53

P Ts

D

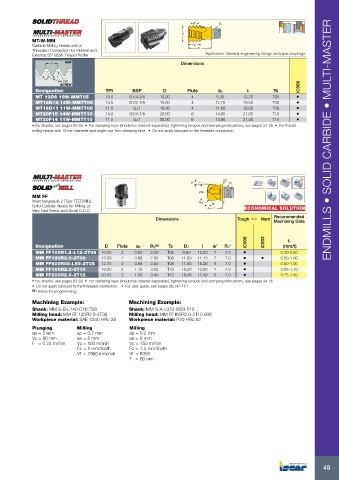

MT-W-MM

Carbide Milling Heads with a ap

Threaded Connection for Internal and l1

External 55° BSW Thread Profile Application: General engineering fittings and pipe couplings

NUT

P Dimensions

55˚

R=0.137P

SCREW IC908

Designation TPI BSP D Flute ap l1 Ts

MT 10D6 19W-MMT05 19.0 G1/4-3/8 10.00 4 5.30 12.75 T05 •

MT16D12 14W-MMTT08 14.0 G1/2-7/8 16.00 4 12.70 19.00 T08 •

MT16D11 11W-MMTT08 11.0 G≥1 16.00 4 11.60 19.00 T08 •

MT20F15 14W-MMTT10 14.0 G3/4-7/8 20.00 6 14.60 21.00 T10 •

MT20F14 11W-MMTT10 11.0 G≥1 20.00 6 13.90 21.00 T10 •

• For shanks, see pages 63-69 • For clamping keys (should be ordered separately), tightening torques and clamping instructions, see pages 34-35 • For thread

milling heads with 12 mm diameter and larger use Torx clamping keys • Do not apply lubricant to the threaded connection

ENDMILLS • SOLID CARBIDE • MULTI-MASTER

D2 Rd°

a° Ts

Dh9

MM FF

Interchangeable 2 Flute FEEDMILL Rg

Solid Carbide Heads for Milling at ap l ECONOMICAL SOLUTION

Very Fast Feeds and Small D.O.C.

Recommended

Dimensions Tough 1 Hard Machining Data

IC908 IC903 fz

Designation D Flute ap Rg (2) Ts D2 l a° Rd° (mm/t)

MM FF100R1.5-L12-2T06 10.00 2 0.60 2.00 T06 9.60 12.50 7 7.0 • 0.30-0.60

MM FF120R2.0-2T08 12.00 2 0.68 2.50 T08 11.50 11.10 7 7.0 • • 0.50-1.00

MM FF500R08-L59-2T08 12.70 2 0.68 2.50 T08 11.50 15.00 5 7.0 • 0.50-1.00

MM FF160R2.0-2T10 16.00 2 1.10 3.00 T10 15.20 13.50 7 7.0 • 0.55-1.10

MM FF200R2.0-2T12 20.00 2 1.50 3.40 T12 18.45 17.40 5 7.0 • 0.75-1.50

• For shanks, see pages 63-69 • For clamping keys (should be ordered separately), tightening torques and clamping instructions, see pages 34-35

• Do not apply lubricant to the threaded connection. • For user guide, see pages 38,147-151

(2) Radius for programming

Machining Example: Machining Example:

Shank: MM S-B-L140-C16-T08 Shank: MM S-A-L070-W20-T10

Milling head: MM FF 120R2.0-2T08 Milling head: MM FF160R2.0-2T10 908

Workpiece material: SAE 4340 HRc 28 Workpiece material: P20 HRc 52

Plunging Milling Milling

ap = 2 mm ap = 0.7 mm ap = 0.2 mm

Vc = 80 mm ae = 8 mm ae = 6 mm

F = 0.24 m/min Vc = 150 m/min Vc = 150 m/min

Fz = 1 mm/tooth Fz = 1.4 mm/tooth

Vf = 7960 mm/min Vf = 8355

T = 60 min

49