Page 50 - Iscar

P. 50

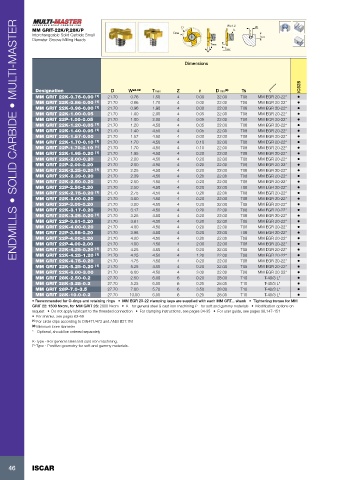

ENDMILLS • SOLID CARBIDE • MULTI-MASTER

W≤1.2

MM GRIT-22K/P,28K/P D Ts r W

Interchangeable Solid Carbide Small Dmin Tmax

Diameter Groove Milling Heads

Tmax

Tmax

W

Dimensions

IC528

Designation D W ±0.02 Tmax Z r D min (2) Ts

MM GRIT 22K-0.76-0.00 (1) 21.70 0.76 1.50 4 0.00 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-0.86-0.00 (1) 21.70 0.86 1.70 4 0.00 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-0.96-0.00 (1) 21.70 0.96 1.90 4 0.00 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-1.00-0.05 21.70 1.00 2.00 4 0.05 22.00 T08 MM EGR 20-22* •

MM GRIT 22P-1.00-0.05 21.70 1.00 2.00 4 0.05 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-1.20-0.05 (1) 21.70 1.20 4.50 4 0.05 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-1.40-0.05 (1) 21.70 1.40 4.50 4 0.05 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-1.57-0.00 21.70 1.57 4.50 4 0.00 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-1.70-0.10 (1) 21.70 1.70 4.50 4 0.10 22.00 T08 MM EGR 20-22* •

MM GRIT 22P-1.70-0.10 (1) 21.70 1.70 4.50 4 0.10 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-1.95-0.20 (1) 21.70 1.95 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-2.00-0.20 21.70 2.00 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22P-2.00-0.20 21.70 2.00 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-2.25-0.20 (1) 21.70 2.25 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-2.39-0.20 21.70 2.39 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-2.50-0.20 21.70 2.50 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22P-2.50-0.20 21.70 2.50 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-2.75-0.20 (1) 21.70 2.75 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-3.00-0.20 21.70 3.00 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22P-3.00-0.20 21.70 3.00 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-3.17-0.20 21.70 3.17 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-3.25-0.20 (1) 21.70 3.25 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22P-3.81-0.20 21.70 3.81 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-4.00-0.20 21.70 4.00 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22P-3.98-0.20 21.70 3.98 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22P-4.00-0.20 21.70 4.00 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22P-4.00-2.00 21.70 4.00 4.50 4 2.00 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-4.25-0.20 (1) 21.70 4.25 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-4.25-1.20 (1) 21.70 4.25 4.50 4 1.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-4.75-0.20 21.70 4.75 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-5.25-0.20 (1) 21.70 5.25 4.50 4 0.20 22.00 T08 MM EGR 20-22* •

MM GRIT 22K-6.00-3.00 21.70 6.00 4.50 4 3.00 22.00 T08 MM EGR 20-22* •

MM GRIT 28K-2.50-0.2 27.70 2.50 6.00 6 0.20 28.00 T10 T-40/3 L* •

MM GRIT 28K-5.25-0.2 27.70 5.25 6.00 6 0.20 28.00 T10 T-40/3 L* •

MM GRIT 28P-7.0-3.5 27.70 7.00 5.70 6 3.50 28.00 T10 T-40/3 L* •

MM GRIT 28K-10.0-0.2 27.70 10.00 6.00 6 0.20 28.00 T10 T-40/3 L* •

• Recommended for O-rings and retaining rings • MM EGR 20-22 clamping keys are supplied with each MM GRT... shank • Tightening torque for MM

GRIT 22: 1500 Nxcm, for MM GRIT 28: 2800 Nxcm • K - for general steel & cast iron machining P - for soft and gummy materials • Modification options on

request • Do not apply lubricant to the threaded connection • For clamping instructions, see pages 34-35 • For user guide, see pages 38,147-151

• For shanks, see pages 63-69

(1) For circle clips according to DIN471/472 and ANSI B27.7M

(2) Minimum bore diameter

* Optional, should be ordered separately

K-Type - For general steel and cast iron machining.

P-Type - Positive geometry for soft and gummy materials.

46 ISCAR