Page 47 - Iscar

P. 47

l Ts

L1

a°

120°

120º D D2

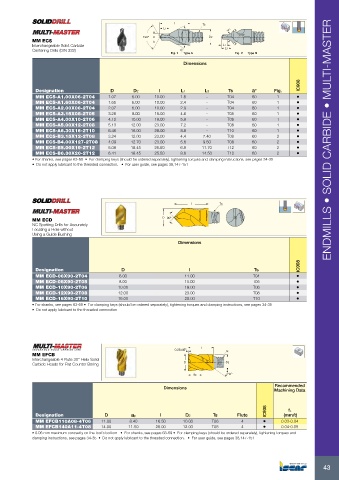

MM ECS

Interchangeable Solid Carbide L1

Centering Drills (DIN 332) a° L3

Fig. 1 Type A Fig. 2 Type B

Dimensions

IC908

Designation D D2 l L1 L3 Ts a° Fig.

MM ECS-A1.00X06-2T04 1.07 6.00 10.00 1.6 - T04 60 1 •

MM ECS-A1.60X06-2T04 1.65 6.00 10.00 2.4 - T04 60 1 •

MM ECS-A2.00X06-2T04 2.07 6.00 10.00 2.9 - T04 60 1 •

MM ECS-A3.15X08-2T05 3.28 8.00 15.00 4.6 - T05 60 1 •

MM ECS-A4.00X10-2T06 4.12 10.00 19.00 5.9 - T06 60 1 •

MM ECS-A5.00X12-2T08 5.13 12.00 23.00 7.2 - T08 60 1 •

MM ECS-A6.30X16-2T10 6.46 16.00 28.00 8.9 - T10 60 1 •

MM ECS-B3.15X12-2T08 3.24 12.00 23.00 4.4 7.40 T08 60 2 •

MM ECS-B4.00X127-2T08 4.09 12.70 23.00 5.6 9.50 T08 60 2 • ENDMILLS • SOLID CARBIDE • MULTI-MASTER

MM ECS-B5.00X19-2T12 5.09 18.45 25.50 6.9 11.70 T12 60 2 •

MM ECS-B6.30X20-2T12 6.41 18.45 25.50 8.6 14.50 T12 60 2 •

• For shanks, see pages 63-69 • For clamping keys (should be ordered separately), tightening torques and clamping instructions, see pages 34-35

• Do not apply lubricant to the threaded connection. • For user guide, see pages 38,147-151

l Ts

D 90°

MM ECD

NC Spotting Drills for Accurately

Locating a Hole without

Using a Guide Bushing

Dimensions

IC908

Designation D l Ts

MM ECD-06X90-2T04 6.00 11.00 T04 •

MM ECD-08X90-2T05 8.00 15.00 T05 •

MM ECD-10X90-2T06 10.00 19.00 T06 •

MM ECD-12X90-2T08 12.00 23.00 T08 •

MM ECD-16X90-2T10 16.00 28.00 T10 •

• For shanks, see pages 63-69 • For clamping keys (should be ordered separately), tightening torques and clamping instructions, see pages 34-35

• Do not apply lubricant to the threaded connection

0.25x45° l Ts

MM EFCB

Interchangeable 4 Flute 30° Helix Solid D

Carbide Heads for Flat Counter Boring D2

Ha°

ap

Recommended

Dimensions

Machining Data

IC908 fz

Designation D ap l D2 Ts Flute (mm/t)

MM EFCB110A08-4T06 11.00 8.40 16.50 10.00 T06 4 • 0.03-0.04

MM EFCB140A11-4T08 14.00 11.50 28.00 12.00 T08 4 • 0.04-0.05

• 0.06 mm maximum concavity on the tool's bottom • For shanks, see pages 63-69 • For clamping keys (should be ordered separately), tightening torques and

clamping instructions, see pages 34-35 • Do not apply lubricant to the threaded connection. • For user guide, see pages 38,147-151

43