Page 449 - Iscar

P. 449

S AN-R-W S AN-N-W AN-14R-W

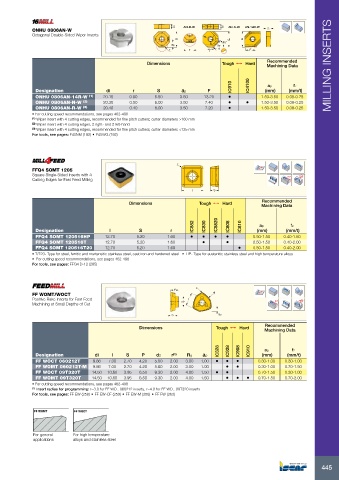

ONHU 0806AN-W S

Octagonal Double-Sided Wiper Inserts L

di 45˚ di di

ap R ap

r F F r F

Recommended

Dimensions Tough 1 Hard

Machining Data MILLING INSERTS

IC910 IC4100 ap fz

Designation di r S ap F (mm) (mm/t)

ONHU 0806AN-14R-W (1) 20.15 0.50 5.50 3.50 13.20 • 1.50-3.50 0.08-0.25

ONHU 0806AN-N-W (2) 20.30 0.50 6.00 3.50 7.40 • • 1.50-3.50 0.08-0.25

ONHU 0806AN-R-W (3) 20.40 0.40 6.00 3.50 7.20 • 1.50-3.50 0.08-0.25

• For cutting speed recommendations, see pages 462-498

(1) Wiper insert with 4 cutting edges, recommended for fine pitch cutters; cutter diameters >160 mm

(2) Wiper insert with 4 cutting edges, 2 right- and 2 left-hand

(3) Wiper insert with 4 cutting edges, recommended for fine pitch cutters; cutter diameters <125 mm

For tools, see pages: F45NM (192) • F45WG (192)

r

FFQ4 SOMT 1205

Square Single-Sided Inserts with 4 Rd°

Cutting Edges for Fast Feed Milling

l S

Recommended

Dimensions Tough 1 Hard

Machining Data

IC882 IC830 IC5820 IC808 IC810 ap fz

Designation l S r (mm) (mm/t)

FFQ4 SOMT 120516HP 12.70 5.20 1.60 • • • • 0.50-1.50 0.40-1.80

FFQ4 SOMT 120516T 12.70 5.20 1.60 • • 0.50-1.50 0.40-2.00

FFQ4 SOMT 120516T20 12.70 5.20 1.60 • 0.50-1.50 0.40-2.00

• T/T20- Type for steel, ferritic and martensitic stainless steel, cast iron and hardened steel • HP- Type for austenitic stainless steel and high temperature alloys

• For cutting speed recommendations, see pages 462-498

For tools, see pages: FFQ4 D-12 (265)

P r

FF WOMT/WOCT di

Positive Rake Inserts for Fast Feed l Rd°

Machining at Small Depths of Cut d2

S ap

Recommended

Dimensions Tough 1 Hard

Machining Data

IC328 IC928 IC908 IC910 ap fz

Designation di l S P d2 r (1) Rg ap (mm) (mm/t)

FF WOCT 060212T 9.86 7.00 2.70 4.20 5.60 2.00 3.00 1.00 • • • 0.30-1.00 0.30-1.00

FF WOMT 060212T-M 9.86 7.00 2.70 4.20 5.60 2.00 3.00 1.00 • • 0.30-1.00 0.70-1.50

FF WOCT 09T320T 14.50 10.60 3.95 6.50 9.30 2.00 4.00 1.50 • • 0.70-1.50 0.30-1.00

FF WOMT 09T320T 14.50 10.60 3.95 6.50 9.30 2.00 4.00 1.50 • • • 0.70-1.50 0.70-2.00

• For cutting speed recommendations, see pages 462-498

(1) Insert radius for programming: r=3.0 for FF WO.. 060212 inserts, r=4.0 for FF WO.. 09T320 inserts

For tools, see pages: FF EW (258) • FF EW-CF (259) • FF EW-M (259) • FF FW (263)

FF WOMT FF WOCT

For general For high temperature

applications alloys and stainless steel

445