Page 103 - Iscar

P. 103

Ch x 45° Rd°

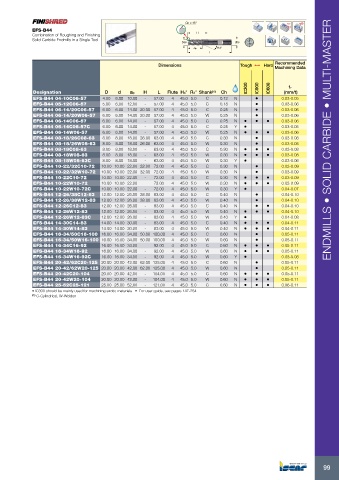

EFS-B44 H

Combination of Roughing and Finishing

Solid Carbide Endmills in a Single Tool

De8 dh6

ap Haº

L

Recommended

Dimensions Tough 1 Hard

Machining Data

IC300 IC900 IC608 fz

Designation D d ap H L Flute Ha° Rd° Shank (1) Ch (mm/t)

EFS-B44 04-10C06-57 4.00 6.00 10.00 - 57.00 4 45.0 5.0 C 0.12 N • 0.03-0.05

EFS-B44 05-12C06-57 5.00 6.00 12.00 - 57.00 4 45.0 5.0 C 0.18 N • 0.03-0.06

EFS-B44 06-14/20C06-57 6.00 6.00 14.00 20.00 57.00 4 45.0 5.0 C 0.25 N • 0.03-0.06

EFS-B44 06-14/20W06-57 6.00 6.00 14.00 20.00 57.00 4 45.0 5.0 W 0.25 N • 0.03-0.06

EFS-B44 06-14C06-57 6.00 6.00 14.00 - 57.00 4 45.0 5.0 C 0.25 N • • • 0.03-0.06

EFS-B44 06-14C06-57C 6.00 6.00 14.00 - 57.00 4 45.0 5.0 C 0.25 Y • 0.03-0.05

EFS-B44 06-14W06-57 6.00 6.00 14.00 - 57.00 4 45.0 5.0 W 0.25 N • • • 0.03-0.06

EFS-B44 08-18/26C08-63 8.00 8.00 18.00 26.00 63.00 4 45.0 5.0 C 0.30 N • 0.03-0.08 ENDMILLS • SOLID CARBIDE • MULTI-MASTER

EFS-B44 08-18/26W08-63 8.00 8.00 18.00 26.00 63.00 4 45.0 5.0 W 0.30 N • 0.03-0.08

EFS-B44 08-18C08-63 8.00 8.00 18.00 - 63.00 4 45.0 5.0 C 0.30 N • • • 0.03-0.08

EFS-B44 08-18W08-63 8.00 8.00 18.00 - 63.00 4 45.0 5.0 W 0.30 N • • • 0.03-0.08

EFS-B44 08-18W08-63C 8.00 8.00 18.00 - 63.00 4 45.0 5.0 W 0.30 Y • 0.03-0.06

EFS-B44 10-22/32C10-72 10.00 10.00 22.00 32.00 72.00 4 45.0 5.0 C 0.30 N • 0.03-0.09

EFS-B44 10-22/32W10-72 10.00 10.00 22.00 32.00 72.00 4 45.0 5.0 W 0.30 N • 0.03-0.09

EFS-B44 10-22C10-72 10.00 10.00 22.00 - 72.00 4 45.0 5.0 C 0.30 N • • • 0.03-0.09

EFS-B44 10-22W10-72 10.00 10.00 22.00 - 72.00 4 45.0 5.0 W 0.30 N • • • 0.03-0.09

EFS-B44 10-22W10-72C 10.00 10.00 22.00 - 72.00 4 45.0 5.0 W 0.30 Y • 0.04-0.07

EFS-B44 12-26/38C12-83 12.00 12.00 26.00 38.00 83.00 4 45.0 5.0 C 0.40 N • 0.04-0.10

EFS-B44 12-26/38W12-83 12.00 12.00 26.00 38.00 83.00 4 45.0 5.0 W 0.40 N • 0.04-0.10

EFS-B44 12-26C12-83 12.00 12.00 26.00 - 83.00 4 45.0 5.0 C 0.40 N • • 0.04-0.10

EFS-B44 12-26W12-83 12.00 12.00 26.00 - 83.00 4 45.0 5.0 W 0.40 N • • • 0.04-0.10

EFS-B44 12-26W12-83C 12.00 12.00 26.00 - 83.00 4 45.0 5.0 W 0.40 Y • 0.04-0.08

EFS-B44 14-30C14-83 14.00 14.00 30.00 - 83.00 4 45.0 5.0 C 0.40 N • • • 0.04-0.11

EFS-B44 14-30W14-83 14.00 14.00 30.00 - 83.00 4 45.0 5.0 W 0.40 N • • • 0.04-0.11

EFS-B44 16-34/50C16-100 16.00 16.00 34.00 50.00 100.00 4 45.0 5.0 C 0.60 N • 0.05-0.11

EFS-B44 16-34/50W16-100 16.00 16.00 34.00 50.00 100.00 4 45.0 5.0 W 0.60 N • 0.05-0.11

EFS-B44 16-34C16-92 16.00 16.00 34.00 - 92.00 4 45.0 5.0 C 0.60 N • • • 0.05-0.11

EFS-B44 16-34W16-92 16.00 16.00 34.00 - 92.00 4 45.0 5.0 W 0.60 N • • • 0.05-0.11

EFS-B44 16-34W16-92C 16.00 16.00 34.00 - 92.00 4 45.0 5.0 W 0.60 Y • 0.05-0.08

EFS-B44 20-42/62C20-125 20.00 20.00 42.00 62.00 125.00 4 45.0 5.0 C 0.60 N • 0.05-0.11

EFS-B44 20-42/62W20-125 20.00 20.00 42.00 62.00 125.00 4 45.0 5.0 W 0.60 N • 0.05-0.11

EFS-B44 20-42C20-104 20.00 20.00 42.00 - 104.00 4 45.0 5.0 C 0.60 N • • • 0.05-0.11

EFS-B44 20-42W20-104 20.00 20.00 42.00 - 104.00 4 45.0 5.0 W 0.60 N • • • 0.05-0.11

EFS-B44 25-52C25-121 25.00 25.00 52.00 - 121.00 4 45.0 5.0 C 0.60 N • • • 0.06-0.11

• IC300 should be mainly used for machining exotic materials • For user guide, see pages 147-254

(1) C-Cylindrical, W-Weldon

99