Page 560 - Dormer

P. 560

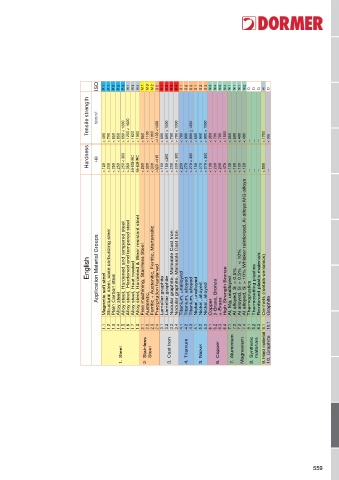

ISO P 1 P 1 P 2 P 3 P 4 H 1 H 3 H 4 M 1 M 3 M 2 S 2 K 1 K 2 K 3 K 4 S 1 S 2 S 3 S 1 S 2 S 3 N 3 N 4 N 3 N 4 N 1 N 1 N 1 N 2 O O O H O

Tensile strength N/mm 2

< 400 < 700 < 850 < 850 > 850 < 1200 > 1200 < 1620 > 1620 > 1980 < 850 < 1100 < 1000 >1100 <1400 > 500 > 500 < 1000 < 700 > 700 < 1000 < 700 < 900 > 900 ≤ 1250 < 500 > 900 > 900 < 1200 < 350 < 700 < 700 < 1500 < 350 < 500 < 400 < 400 --- --- --- < 1700 < 100

Hardness HB < 120 < 200 < 250 < 250 > 250 < 350 > 350 49-55HRC 55-63HRC < 250 < 320 < 300 >320 <410 < 150 > 150 <300 < 200 > 200 < 300 < 200 < 270 > 270 < 350 < 150 < 270 > 270 < 350 < 100 < 200 < 200 < 470 < 100 < 150 < 120 < 120 --- --- --- < 550 ---

English Application Material Groups Magnetic soft steel Structural steel, case carburizing steel Plain Carbon steel Alloy steel, Hardened and tempered steel Alloy steel, Hardened and tempered steel Alloy steel, Heat treated Alloy steel, Hardened & Wear resistant steel Free machining, Stainless Steel Ferritic + Austenitic, Ferritic, Martensitic Precipitation hardened Lamellar graphite Lamellar graphite Nodular graphite, Malleable Cast

1.1 1.2 1.3 Alloy steel 1.4 1.5 1.6 1.7 1.8 2.1 Austenitic, 2.2. 2.3 2.4 3.1 3.2 3.3 3.4 4.1 4.2 4.3 5.1 Nickel, alloyed 5.2 Nickel, alloyed 5.3 Copper 6.1 6.2 α-Brass 6.3 6.4 7.1 7.2 7.3 7.4 8.1 8.2 8.3 9,1 Graphite 10.1

1. Steel 2. Stainless Steel 3. Cast Iron 4. Titanium 5. Nickel 6. Copper 7. Aluminium Magnesium 8. Synthetic materials 9. Hard material 10. Graphite

559