Page 203 - DC

P. 203

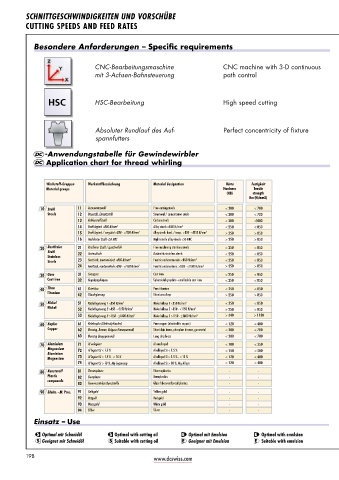

SCHNITTGESCHWINDIGKEITEN UND VORSCHÜBE

CUTTING SPEEDS AND FEED RATES

Besondere Anforderungen – Specific requirements

CNC-Bearbeitungsmaschine CNC machine with 3-D continuous

mit 3-Achsen-Bahnsteuerung path control

HSC HSC-Bearbeitung High speed cutting

Absoluter Rundlauf des Auf- Perfect concentricity of fixture

spannfutters

-Anwendungstabelle für Gewindewirbler

Application chart for thread whirling

Werkstoff-Gruppen Werkstoffbezeichnung Material designation Härte Festigkeit GW1016VS GW2016VS GW3016VS GW3019VS GW4016VS GW4019VS

Material groups Hardness Tensile GW1016 GW2016 GW3016 GW3019 GW4016 GW4019

(HB) strength

Rm (N/mm2)

10 Stahl 11 Automatenstahl Free-cutting steels < 200 < 700 S E S E S E S E S E S E S E S E 60 – 80 80 – 100 0.004 – 0.01 0.01 – 0.05 0.04 – 0.10 0.08 – 0.15 11

Steels 12 Baustahl, Einsatzstahl Structural / cementation steels < 200 < 700 S E S E S E S E S E S E S E S E 60 – 80 80 – 100 0.004 – 0.01 0.01 – 0.05 0.04 – 0.10 0.08 – 0.15 12

13 Kohlenstoffstahl Carbon steels < 300 <1000 S E S E S E S E S E S E S E S E 50 – 70 70 – 90 0.004 – 0.01 0.01 – 0.05 0.02 – 0.10 0.05 – 0.15 13

14 Stahl legiert <850 N/mm 2 Alloy steels <850 N/mm 2 < 250 < 850 S E S E S E S E S E S E S E S E 50 – 70 70 – 90 0.004 – 0.01 0.01 – 0.05 0.02 – 0.10 0.05 – 0.15 14

15 Stahl legiert / vergütet >850 - <1150 N/mm 2 Alloy steels hard. / temp. >850 - <1150 N/mm 2 > 250 > 850 S E S E S E S E S E S E S E S E 15 – 35 30 – 50 0.004 – 0.01 0.01 – 0.05 0.02 – 0.08 0.04 – 0.15 15

16 Hochfester Stahl <55 HRC High tensile alloy steels <55 HRC > 250 > 850 S E S E S E S E 15 – 40 0.003 – 0.01 0.006 – 0.03 0.008 – 0.05 0.01 – 0.08 16

20 Rostfreier 21 Rostfreier Stahl / geschwefelt Free machining stainless steels < 250 < 850 S E S E S E S E 40 – 60 0.004 – 0.01 0.01 – 0.05 0.02 – 0.10 0.05 – 0.15 21

Stahl 22 Austenitisch Austenitic stainless steels < 250 < 850 S E S E S E S E 30 – 50 0.004 – 0.01 0.01 – 0.03 0.02 – 0.05 0.03 – 0.08 22

Stainless

Steels 23 Ferritisch, martensitisch <850 N/mm 2 Ferritic and martensitic <850 N/mm 2 < 250 < 850 S E S E S E S E 30 – 50 0.004 – 0.01 0.01 – 0.03 0.02 – 0.05 0.03 – 0.08 23

24 Ferritisch, martensitisch >850 - <1150 N/mm 2 Ferritic and martens. >850 - <1150 N/mm 2 > 250 > 850 S E S E S E S E 30 – 50 0.004 – 0.01 0.01 – 0.03 0.02 – 0.05 0.03 – 0.08 24

30 Guss 31 Grauguss Cast iron < 250 < 850 S E S E S E S E S E S E S E S E 60 – 90 90 – 120 0.004 – 0.01 0.01 – 0.05 0.04 – 0.10 0.08 – 0.15 31

Cast iron 32 Kugelgraphitguss Spheroidal graphite + malleable cast iron < 250 < 850 S E S E S E S E S E S E S E S E 50 – 70 70 – 90 0.004 – 0.01 0.01 – 0.05 0.02 – 0.10 0.05 – 0.15 32

40 Titan 41 Reintitan Pure titanium < 250 < 850 S E S E S E S E S E S E S E S E 15 – 35 20 – 40 0.004 – 0.01 0.01 – 0.03 0.02 – 0.05 0.03 – 0.08 41

Titanium 42 Titanlegierung Titanium alloys > 250 > 850 S E S E S E S E S E S E S E S E 10 – 30 15 – 35 0.004 – 0.01 0.01 – 0.03 0.02 – 0.05 0.03 – 0.08 42

50 Nickel 51 Nickellegierung 1 <850 N/mm 2 Nickel alloys 1 <850 N/mm 2 < 250 < 850 S E S E S E S E 20 – 40 0.004 – 0.01 0.01 – 0.03 0.02 – 0.05 0.03 – 0.08 51

Nickel 52 Nickellegierung 2 >850 - <1150 N/mm 2 Nickel alloys 2 >850 - <1150 N/mm 2 > 250 > 850 S E S E S E S E 20 – 40 0.004 – 0.01 0.01 – 0.03 0.02 – 0.05 0.03 – 0.08 52

53 Nickellegierung 3 >1150 - ≤1600 N/mm 2 Nickel alloys 3 >1150 - ≤1600 N/mm 2 > 340 > 1150 S E S E S E S E 20 – 30 0.003 – 0.01 0.006 – 0.03 0.008 – 0.05 0.01 – 0.08 53

60 Kupfer 61 Reinkupfer (Elektrolytkupfer) Pure copper (electrolitic copper) < 120 < 400 S E S E S E S E S E S E S E S E 150 – 200 200 – 250 0.004 – 0.01 0.01 – 0.05 0.02 – 0.10 0.05 – 0.15 61

Copper 62 Messing, Bronze, Rotguss (kurzspanend) Short chip brass, phosphor bronze, gun metal < 200 < 700 S E S E S E S E S E S E S E S E 100 – 150 150 – 200 0.004 – 0.01 0.01 – 0.05 0.04 – 0.10 0.08 – 0.15 62

63 Messing (langspanend) Long chip brass < 200 < 700 S E S E S E S E S E S E S E S E 100 – 150 150 – 200 0.004 – 0.01 0.01 – 0.05 0.02 – 0.10 0.05 – 0.15 63

70 Aluminium 71 Al unlegiert Al unalloyed < 100 < 350 S E S E S E S E 150 – 250 0.004 – 0.01 0.01 – 0.05 0.05 – 0.10 0.10 – 0.20 71

Magnesium 72 Al legiert Si < 1.5 % Al alloyed Si < 1.5 % < 150 < 500 S E S E S E S E 150 – 250 0.004 – 0.01 0.01 – 0.05 0.05 – 0.10 0.10 – 0.20 72

Aluminium

Magnesium 73 Al legiert Si > 1.5 % - < 10 % Al alloyed Si > 1.5 % - < 10 % < 120 < 400 S E S E S E S E S E S E S E S E 150 – 250 200 – 300 0.004 – 0.01 0.01 – 0.05 0.05 – 0.10 0.10 – 0.20 73

74 Al legiert Si > 10 %, Mg-Legierung Al alloyed Si > 10 %, Mg-Alloys < 120 < 400 S E S E S E E S E S E E S E S E S E 150 – 250 200 – 300 0.004 – 0.01 0.01 – 0.05 0.04 – 0.10 0.08 – 0.15 74

80 Kunststoff 81 Thermoplaste Thermoplastics - - E E E E E E E E E E E E 150 – 250 200 – 300 0.004 – 0.01 0.01 – 0.05 0.05 – 0.10 0.10 – 0.20 81

Plastic 82 Duroplaste Duroplastics - - E E E E E E E E E E E E 80 – 150 100 – 200 0.004 – 0.01 0.01 – 0.05 0.04 – 0.10 0.08 – 0.15 82

compounds

83 Faserverstärkte Kunststoffe Glass fibre reinforced plastics - - E E E E E E 80 – 100 0.004 – 0.01 0.01 – 0.05 0.04 – 0.10 0.08 – 0.15 83

90 Edelm. - M. Prec. 91 Gelbgold Yellow gold - - S E S E S E S E S E S E S E S E 100 – 150 150 – 200 0.004 – 0.01 0.01 – 0.05 0.04 – 0.10 0.08 – 0.15 91

92 Rotgold Red gold - - S E S E S E S E S E S E S E S E 60 – 90 90 – 120 0.004 – 0.01 0.01 – 0.05 0.02 – 0.10 0.04 – 0.15 92

93 Weissgold White gold - - S E S E E S E E S E 30 – 50 0.004 – 0.01 0.01 – 0.03 0.02 – 0.05 0.03 – 0.08 93

94 Silber Silver - - S E S E S E S E S E S E S E S E 60 – 90 90 – 120 0.004 – 0.01 0.01 – 0.05 0.02 – 0.10 0.04 – 0.15 94

Einsatz – Use

S Optimal mit Schneidöl S Optimal with cutting oil E Optimal mit Emulsion E Optimal with emulsion

S Geeignet mit Schneidöl S Suitable with cutting oil E Geeignet mit Emulsion E Suitable with emulsion

198