Page 196 - DC

P. 196

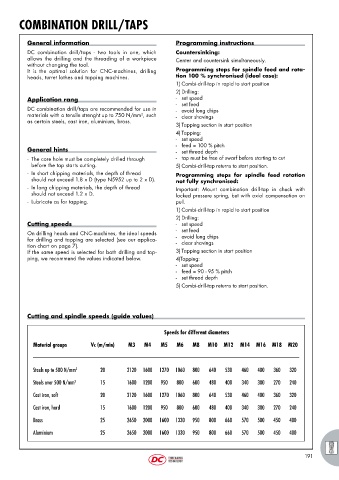

COMBINATION DRILL/TAPS

General information Programming instructions

DC combination drill/taps - two tools in one, which Countersinking:

allows the drilling and the threading of a workpiece Center and countersink simultaneously.

without changing the tool.

It is the optimal solution for CNC-machines, drilling Programming steps for spindle feed and rota-

heads, turret lathes and tapping machines. tion 100 % synchronised (ideal case):

1) Combi-drill-tap in rapid to start position

2) Drilling:

Application rang - set speed

- set feed

DC combination drill/taps are recommended for use in - avoid long chips

materials with a tensile strenght up to 750 N/mm , such - clear shavings

2

as certain steels, cast iron, aluminium, brass.

3) Tapping section in start position

4) Tapping:

- set speed

- feed = 100 % pitch

General hints - set thread depth

- The core hole must be completely drilled through - tap must be free of swarf before starting to cut

before the tap starts cutting. 5) Combi-drill-tap returns to start position.

- In short chipping materials, the depth of thread Programming steps for spindle feed rotation

should not exceed 1.8 x D (type N5952 up to 2 x D). not fully synchronised:

- In long chipping materials, the depth of thread Important: Mount combination drill-tap in chuck with

should not exceed 1.2 x D. locked pressure spring, but with axial compensation on

- Lubricate as for tapping. pull.

1) Combi-drill-tap in rapid to start position

2) Drilling:

Cutting speeds - set speed

- set feed

On drilling heads and CNC-machines, the ideal speeds

for drilling and tapping are selected (see our applica- - avoid long chips

tion chart on page 7). - clear shavings

If the same speed is selected for both drilling and tap- 3) Tapping section in start position

ping, we recommend the values indicated below. 4)Tapping:

- set speed

- feed = 90 - 95 % pitch

- set thread depth

5) Combi-drill-tap returns to start position.

Cutting and spindle speeds (guide values)

Speeds for different diameters

Material groups Vc (m/min) M3 M4 M5 M6 M8 M10 M12 M14 M16 M18 M20

Steels up to 500 N/mm 20 2120 1600 1270 1060 800 640 530 460 400 360 320

2

Steels over 500 N/mm 15 1600 1200 950 800 600 480 400 340 300 270 240

2

Cast iron, soft 20 2120 1600 1270 1060 800 640 530 460 400 360 320

Cast iron, hard 15 1600 1200 950 800 600 480 400 340 300 270 240

Brass 25 2650 2000 1600 1330 950 800 660 570 500 450 400

Aluminium 25 2650 2000 1600 1330 950 800 660 570 500 450 400

191

THREADING

TECHNOLOGY