Page 83 - logic

P. 83

USER GUIDE Engineered for

Performance

MAXIMUM

MULTI-MASTER

Ball Nose

• For die & mold making, turbine manufacturing and

aircraft industry, etc.

• Useful for intricate-shaped surfaces.

• Profiling of up to 70 HRc high hardened steels and

alloy steels, nickel based alloys, titanium alloys.

• Ultra-fine grain carbide which increases both

toughness and hardness.

• Suitable for dry and high speed cutting.

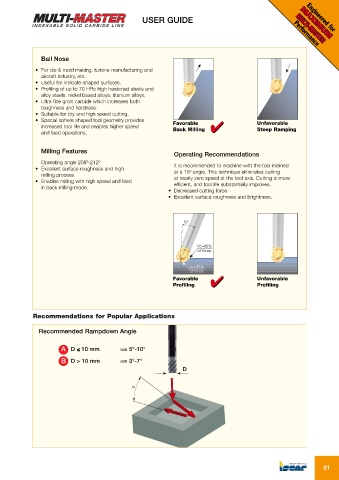

• Special sphere shaped tool geometry provides Favorable Unfavorable

increased tool life and enables higher speed Back Milling Steep Ramping

and feed operations.

Milling Features Operating Recommendations

Operating angle 208º-212º

• Excellent surface roughness and high It is recommended to machine with the tool inclined

milling process. at a 15º angle. This technique eliminates cutting

• Enables milling with high speed and feed at nearly zero speed at the tool axis. Cutting is more

in back milling mode. efficient, and tool life substantially improves.

• Decreased cutting force.

• Excellent surface roughness and brightness.

15˚

Vc=96%

of Vmax

Vc=26%

of Vmax

Favorable Unfavorable

Profiling Profiling

Recommendations for Popular Applications

Recommended Rampdown Angle

A D ≤ 10 mm a= 5°-10°

B D > 10 mm a= 3°-7°

D

α

81