Page 80 - logic

P. 80

USER GUIDE

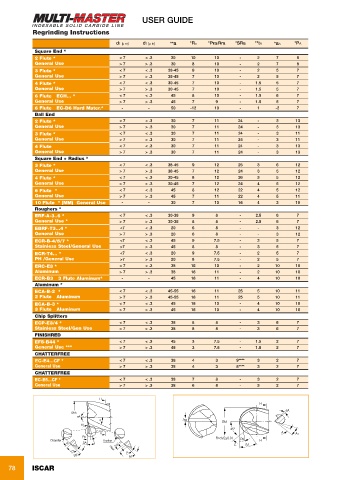

Regrinding Instructions

d1 [µ m] d1 [µ in] **a *Ra *Pra/Rra *SRa **tA *aA *PA

Square End *

2 Flute * < 7 < .3 30 10 10 - 2 7 8

General Use > 7 > .3 30 8 10 - 2 7 8

3 Flute * < 7 < .3 38-45 9 10 - 2 5 7

General Use > 7 > .3 38-45 7 10 - 2 5 7

4 Flute * < 7 < .3 30-45 7 10 - 1.5 5 7

General Use > 7 > .3 30-45 7 10 - 1.5 5 7

6 Flute ECH… * < 7 < .3 45 8 10 - 1.5 6 7

General Use > 7 > .3 45 7 9 - 1.5 5 7

6 Flute EC-D6 Hard Mater.* - - 50 -12 10 - 1 -2 7

Ball End

2 Flute * < 7 < .3 30 7 11 24 - 3 13

General Use > 7 > .3 30 7 11 24 - 3 13

3 Flute * < 7 < .3 30 7 11 24 - 3 11

General Use > 7 > .3 30 7 11 24 - 3 11

4 Flute < 7 < .3 30 7 11 24 - 3 13

General Use > 7 > .3 30 7 11 24 - 3 13

Square End + Radius *

3 Flute * < 7 < .3 38-45 9 12 25 3 6 12

General Use > 7 > .3 38-45 7 12 24 3 5 12

4 Flute * < 7 < .3 30-45 8 12 26 3 5 12

General Use > 7 > .3 30-45 7 12 24 4 5 12

6 Flute * < 7 < .3 45 8 12 22 4 5 12

General Use > 7 > .3 45 7 11 22 4 5 11

10 Flute * (MM) General Use - - 30 7 10 16 4 3 10

Roughers *

ERF-A-3..6 * < 7 < .3 30-38 9 8 - 2.5 6 7

General Use * > 7 > .3 30-38 8 8 - 2.5 6 7

EBRF-T3…4 * <7 < .3 20 6 8 - - 3 12

General Use > 7 > .3 20 6 8 - - 3 12

ECR-B-4/5/7 * <7 < .3 45 9 7.5 - 3 5 7

Stainless Steel/General Use >7 > .3 45 8 8 - 3 5 7

ECR-T4… * <7 < .3 20 9 7.5 - 2 5 7

PH /General Use >7 > .3 20 8 7.5 - 2 5 7

ERC-E3 * < 7 < .3 38 16 10 - 2 10 10

Aluminum > 7 > .3 38 16 11 - 2 10 10

ECR-B3 3 Flute Aluminum* - - 45 16 11 - 4 10 10

Aluminum *

ECA-B-2 * < 7 < .3 45-55 16 11 25 5 10 11

2 Flute Aluminum > 7 > .3 45-55 16 11 25 5 10 11

ECA-B-3 * < 7 < .3 45 16 10 - 4 10 10

3 Flute Aluminum > 7 > .3 45 16 10 - 4 10 10

Chip Splitters

ECP-E3/4 * < 7 < .3 38 8 8 - 3 6 7

Stainless Steel/Gen Use > 7 > .3 38 8 8 - 3 6 7

FINISHRED

EFS-B44 * < 7 < .3 45 3 7.5 - 1.5 2 7

General Use *** > 7 > .3 45 3 7.5 - 1.5 2 7

CHATTERFREE

EC-E4...CF * < 7 < .3 38 4 3 9**** 3 2 7

General Use > 7 > .3 38 4 3 8**** 3 2 7

CHATTERFREE

EC-E5...CF * < 7 < .3 38 7 8 - 3 2 7

General Use > 7 > .3 38 6 8 - 3 2 7

H

H

aA

Ød1

aA

a Aw

Ød1

tA

45°

H A A1

PA R=d1/2±0.01

Chamfer Radius PA H

P SA P

B C SA

10° A

Heel

20° A1

78 ISCAR