Page 72 - logic

P. 72

FOR INTERNAL USE ONL Y • SUBJECT TO CHANGE

DHUB

DCONMS

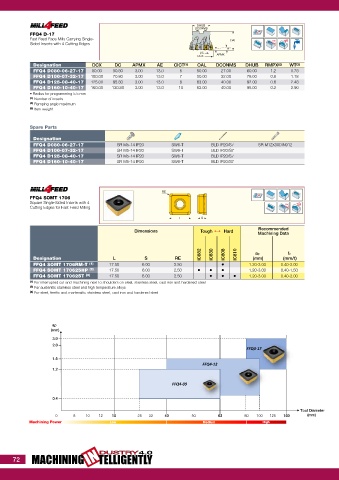

FFQ4 D-17

Fast Feed Face Mills Carrying Single- OAL Rd°

Sided Inserts with 4 Cutting Edges

14°

DC

DCX APMX

Designation DCX DC APMX AE CICT (1) OAL DCONMS DHUB RMPX (2) WT (3)

FFQ4 D080-06-27-17 80.00 50.80 3.00 13.0 6 50.00 27.00 60.00 1.2 0.78

FFQ4 D100-07-32-17 100.00 70.80 3.00 13.0 7 50.00 32.00 78.00 0.8 1.18

FFQ4 D125-08-40-17 125.00 95.80 3.00 13.0 8 63.00 40.00 92.00 0.6 2.48

FFQ4 D160-10-40-17 160.00 130.80 3.00 13.0 10 63.00 40.00 95.00 0.2 2.90

• Radius for programming 5.5 mm

(1) Number of inserts

(2) Ramping angle maximum

(3) Item weight

Spare Parts

Designation

FFQ4 D080-06-27-17 SR M5-14 IP20 SW6-T BLD IP20/S7 SR M12X30DIN912

FFQ4 D100-07-32-17 SR M5-14 IP20 SW6-T BLD IP20/S7

FFQ4 D125-08-40-17 SR M5-14 IP20 SW6-T BLD IP20/S7

FFQ4 D160-10-40-17 SR M5-14 IP20 SW6-T BLD IP20/S7

RE

FFQ4 SOMT 1706

Square Single-Sided Inserts with 4 Rd°

Cutting Edges for Fast Feed Milling

L S

Recommended

Dimensions Tough 1 Hard

Machining Data

IC882 IC830 IC808 IC810 ap fz

Designation L S RE (mm) (mm/t)

FFQ4 SOMT 1706RM-T (1) 17.50 6.00 2.50 • 1.20-3.00 0.40-2.00

FFQ4 SOMT 170625HP (2) 17.50 6.00 2.50 • • • 1.20-3.00 0.40-1.50

FFQ4 SOMT 170625T (3) 17.50 6.00 2.50 • • • 1.20-3.00 0.40-2.00

(1) For interrupted cut and machining next to shoulders on steel, stainless steel, cast iron and hardened steel

(2) For austenitic stainless steel and high temperature alloys

(3) For steel, ferritic and martensitic stainless steel, cast iron and hardened steel

ap

(mm)

3.0

2.0

FFQ4-17

1.5

FFQ4-12

1.2

FFQ4-09

0.4

Tool Diameter

0 8 10 12 16 25 32 40 50 63 80 100 125 160 (mm)

Machining Power Low Medium High

DUSTRY 4.0

MACHINING IN TELLIGENTLY

72