Page 71 - logic

P. 71

FOR INTERNAL USE ONL Y • SUBJECT TO CHANGE FOR INTERNAL USE ONL Y • SUBJECT TO CHANGE

RE

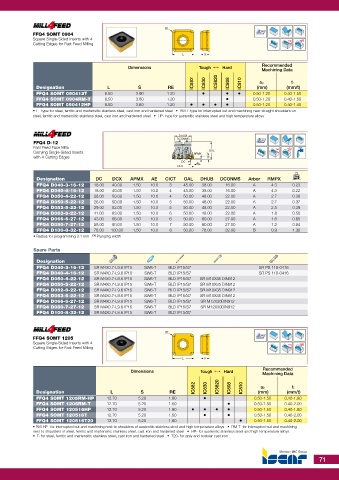

FFQ4 SOMT 0904

Square Single-Sided Inserts with 4 Rd°

Cutting Edges for Fast Feed Milling

L S

Recommended

Dimensions Tough 1 Hard

Machining Data

IC882 IC830 IC5820 IC808 IC810 ap fz

Designation L S RE (mm) (mm/t)

FFQ4 SOMT 090412T 8.50 3.90 1.20 • • • 0.50-1.20 0.40-1.50

FFQ4 SOMT 0904RM-T 8.50 3.80 1.20 • 0.50-1.20 0.40-1.50

FFQ4 SOMT 090412HP 8.50 3.80 1.20 • • • • 0.50-1.20 0.40-1.40

• T - type for steel, ferritic and martensitic stainless steel, cast iron and hardened steel • RM-T type for interrupted cut and machining near straight shoulders on

steel, ferritic and martensitic stainless steel, cast iron and hardened steel • HP- type for austenitic stainless steel and high temperature alloys

DCONMS

DHUB

FFQ4 D-12

Fast Feed Face Mills Rd°

Carrying Single-Sided Inserts APMX OAL

with 4 Cutting Edges 9°

DC AE

DCX

Designation DC DCX APMX AE CICT OAL DHUB DCONMS Arbor RMPX kg

FFQ4 D040-3-16-12 18.00 40.00 1.50 10.0 3 45.00 38.00 16.00 A 4.3 0.23

FFQ4 D040-4-16-12 18.00 40.00 1.50 10.0 4 45.00 38.00 16.00 A 4.3 0.22

FFQ4 D050-4-22-12 28.00 50.00 1.50 10.0 4 50.00 48.00 22.00 A 2.7 0.38

FFQ4 D050-5-22-12 28.00 50.00 1.50 10.0 5 50.00 48.00 22.00 A 2.7 0.37

FFQ4 D052-5-22-12 29.00 52.00 1.50 10.0 5 50.00 48.00 22.00 A 2.5 0.39

FFQ4 D063-6-22-12 41.00 63.00 1.50 10.0 6 50.00 48.00 22.00 A 1.8 0.50

FFQ4 D066-6-27-12 43.00 66.00 1.50 10.0 6 50.00 60.00 27.00 A 1.6 0.65

FFQ4 D080-7-27-12 58.00 80.00 1.50 10.0 7 50.00 60.00 27.00 A 1.2 0.84

FFQ4 D100-8-32-12 78.00 100.00 1.50 10.0 8 50.00 78.00 32.00 B 0.9 1.30

• Radius for programming 3.1 mm (1) Plunging width

Spare Parts

Designation

FFQ4 D040-3-16-12 SR M4X0.7-L9.6 IP15 SW6-T BLD IP15/S7 SR PS 118-0416

FFQ4 D040-4-16-12 SR M4X0.7-L9.6 IP15 SW6-T BLD IP15/S7 SR PS 118-0416

FFQ4 D050-4-22-12 SR M4X0.7-L9.6 IP15 SW6-T BLD IP15/S7 SR M10X35 DIN912

FFQ4 D050-5-22-12 SR M4X0.7-L9.6 IP15 SW6-T BLD IP15/S7 SR M10X35 DIN912

FFQ4 D052-5-22-12 SR M4X0.7-L9.6 IP15 SW6-T BLD IP15/S7 SR M10X35 DIN912

FFQ4 D063-6-22-12 SR M4X0.7-L9.6 IP15 SW6-T BLD IP15/S7 SR M10X35 DIN912

FFQ4 D066-6-27-12 SR M4X0.7-L9.6 IP15 SW6-T BLD IP15/S7 SR M12X30DIN912

FFQ4 D080-7-27-12 SR M4X0.7-L9.6 IP15 SW6-T BLD IP15/S7 SR M12X30DIN912

FFQ4 D100-8-32-12 SR M4X0.7-L9.6 IP15 SW6-T BLD IP15/S7

RE

FFQ4 SOMT 1205

Square Single-Sided Inserts with 4 Rd°

Cutting Edges for Fast Feed Milling

L S

Recommended

Dimensions Tough 1 Hard

Machining Data

IC882 IC830 IC5820 IC808 IC810 ap fz

Designation L S RE (mm) (mm/t)

FFQ4 SOMT 1205RM-HP 12.70 5.20 1.60 • 0.50-1.50 0.40-1.80

FFQ4 SOMT 1205RM-T 12.70 5.20 1.60 • 0.50-1.50 0.40-2.00

FFQ4 SOMT 120516HP 12.70 5.20 1.60 • • • • 0.50-1.50 0.40-1.80

FFQ4 SOMT 120516T 12.70 5.20 1.60 • • 0.50-1.50 0.40-2.00

FFQ4 SOMT 120516T20 12.70 5.20 1.60 • 0.50-1.50 0.40-2.00

• RM-HP- for interrupted cut and machining next to shoulders of austenitic stainless steel and high temperature alloys • RM-T- for interrupted cut and machining

next to shoulders of steel, ferritic and martensitic stainless steel, cast iron and hardened steel • HP- for austenitic stainless steel and high temperature alloys

• T- for steel, ferritic and martensitic stainless steel, cast iron and hardened steel • T20- for grey and nodular cast iron

71