Page 903 - Iscar

P. 903

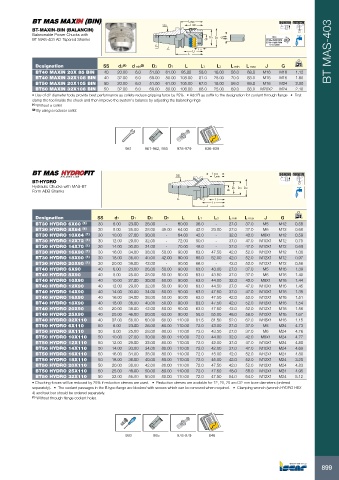

SS Lmax A 0.003 A 58-60 HRc

Lmin

BT-MAXIN-BIN (BALANCIN)

Balanceable Power Chucks with d min G2.5

BT MAS-403 AD Tapered Shanks d2 D3 D1 max BT 40= 20,000 RPM

BT 50= 18,000 RPM

G U<1.0 gmm

J L3

L1 BT MAS-403

L

Designation SS d2 (1) d min (2) D3 D1 L L1 L3 L min L max J G kg

BT40 MAXIN 20X 85 BIN 40 20.00 6.0 51.00 61.00 85.00 58.0 18.00 56.0 68.0 M16 M16 1.12

BT40 MAXIN 32X108 BIN 40 32.00 6.0 69.00 80.00 108.00 81.0 25.00 70.0 83.0 M16 M16 1.60

BT50 MAXIN 20X105 BIN 50 20.00 6.0 51.00 61.00 105.00 67.0 18.00 56.0 69.0 M16 M24 2.00

BT50 MAXIN 32X106 BIN 50 32.00 6.0 69.00 80.00 106.00 68.0 25.00 69.0 83.0 M20X2 M24 2.10

• Use of d2 diameter tools provide best performance as collets reduce gripping force by 25%. • Add B as suffix to the designation for coolant through flange • First

clamp the tool inside the chuck and then improve the system's balance by adjusting the balancing rings

(1) Without a collet

(2) By using a reducer collet

981 961-962, 983 978-979 836-839

SS Lmax A 0.003 A 58-60 HRc

Lmin

BT-HYDRO

Hydraulic Chucks with MAS-BT D1 D3 D2

Form ADB Shanks d2

G J L3

L1

L

Designation SS d2 D1 D3 D2 L L1 L3 L min L max J G kg

BT30 HYDRO 6X60 (1) 30 6.00 23.00 26.00 - 60.00 38.0 - 27.0 37.0 M5 M12 0.58

BT30 HYDRO 8X64 (1) 30 8.00 25.00 28.00 45.00 64.00 42.0 29.00 27.0 37.0 M6 M12 0.68

BT30 HYDRO 10X64 (1) 30 10.00 27.00 30.00 - 64.00 42.0 - 32.0 42.0 M8X1 M12 0.59

BT30 HYDRO 12X72 (1) 30 12.00 29.00 32.00 - 72.00 50.0 - 37.0 47.0 M10X1 M12 0.70

BT30 HYDRO 14X70 (1) 30 14.00 30.00 34.00 - 70.00 48.0 - 37.0 47.0 M10X1 M12 0.69

BT30 HYDRO 16X90 (1) 30 16.00 34.00 38.00 50.00 90.00 63.0 47.50 42.0 52.0 M12X1 M12 1.00

BT30 HYDRO 18X90 (1) 30 18.00 36.00 40.00 42.00 90.00 68.0 52.00 42.0 52.0 M12X1 M12 0.97

BT30 HYDRO 20X90 (1) 30 20.00 38.00 42.00 - 90.00 68.0 - 42.0 52.0 M12X1 M12 0.56

BT40 HYDRO 6X90 40 6.00 23.00 26.00 50.00 90.00 63.0 43.00 27.0 37.0 M5 M16 1.39

BT40 HYDRO 8X90 40 8.00 25.00 28.00 50.00 90.00 63.0 43.50 27.0 37.0 M6 M16 1.40

BT40 HYDRO 10X90 40 10.00 27.00 30.00 50.00 90.00 63.0 44.00 32.0 42.0 M8X1 M16 1.44

BT40 HYDRO 12X90 40 12.00 29.00 32.00 50.00 90.00 63.0 44.50 37.0 47.0 M10X1 M16 1.45

BT40 HYDRO 14X90 40 14.00 30.00 34.00 50.00 90.00 63.0 47.50 37.0 47.0 M10X1 M16 1.35

BT40 HYDRO 16X90 40 16.00 34.00 38.00 50.00 90.00 63.0 47.50 42.0 52.0 M12X1 M16 1.51

BT40 HYDRO 18X90 40 18.00 36.00 40.00 50.00 90.00 63.0 47.50 42.0 52.0 M12X1 M16 1.54

BT40 HYDRO 20X90 40 20.00 38.00 42.00 50.00 90.00 63.0 47.50 42.0 52.0 M12X1 M16 1.56

BT40 HYDRO 25X90 40 25.00 46.00 50.00 63.00 90.00 55.0 55.00 48.0 58.0 M12X1 M16 1.67

BT40 HYDRO 32X110 40 32.00 56.00 60.00 60.00 110.00 81.5 81.50 52.0 62.0 M16X1 M16 1.15

BT50 HYDRO 6X110 50 6.00 23.00 26.00 80.00 110.00 72.0 43.00 27.0 37.0 M5 M24 4.73

BT50 HYDRO 8X110 50 8.00 25.00 28.00 80.00 110.00 72.0 43.50 27.0 37.0 M6 M24 4.76

BT50 HYDRO 10X110 50 10.00 27.00 30.00 80.00 110.00 72.0 44.00 32.0 42.0 M8X1 M24 4.77

BT50 HYDRO 12X110 50 12.00 29.00 32.00 80.00 110.00 72.0 42.00 37.0 47.0 M10X1 M24 4.80

BT50 HYDRO 14X110 50 14.00 30.00 34.00 80.00 110.00 72.0 42.00 37.0 47.0 M10X1 M24 4.69

BT50 HYDRO 16X110 50 16.00 34.00 38.00 80.00 110.00 72.0 45.00 42.0 52.0 M12X1 M24 4.80

BT50 HYDRO 18X110 50 18.00 36.00 40.00 80.00 110.00 72.0 45.00 42.0 52.0 M12X1 M24 3.20

BT50 HYDRO 20X110 50 20.00 38.00 42.00 80.00 110.00 72.0 47.50 42.0 52.0 M12X1 M24 4.83

BT50 HYDRO 25X110 50 25.00 46.00 50.00 80.00 110.00 72.0 47.50 48.0 58.0 M12X1 M24 4.95

BT50 HYDRO 32X110 50 32.00 56.00 60.00 80.00 110.00 72.0 47.50 54.0 64.0 M12X1 M24 5.12

• Chucking forces will be reduced by 25% if reduction sleeves are used. • Reduction sleeves are available for 12, 20, 25 and 32 mm bore diameters (ordered

separately). • The coolant passages in the B type flange are blocked with screws which can be removed when required. • Clamping wrench (wrench HYDRO HEX

4) and test bar should be ordered separately.

(1) Without through flange coolant holes.

993 965 978-979 846

899