Page 809 - Iscar

P. 809

55° 107.5°

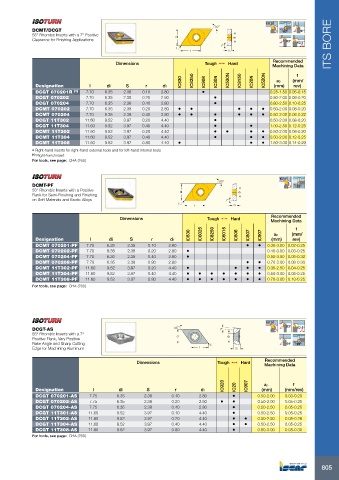

DCMT/DCGT 93º 91°

55° Rhombic Inserts with a 7° Positive di

Clearance for Finishing Applications d1 93° 62.5°

7° ITS BORE

r

l S

Recommended

Dimensions Tough 1 Hard

Machining Data

f

IC830 IC8250 IC908 IC30N IC530N IC8150 IC20N IC520N ap (mm/

Designation l di S r d1 (mm) rev)

DCGT 070201R (1) 7.70 6.35 2.38 0.10 2.80 • 0.25-1.50 0.05-0.15

DCGT 070202 7.70 6.35 2.38 0.20 2.80 • 0.50-2.00 0.08-0.20

DCGT 070204 7.70 6.35 2.38 0.40 2.80 • 0.80-2.50 0.10-0.25

DCMT 070202 7.70 6.35 2.38 0.20 2.80 • • • • • 0.50-2.00 0.08-0.20

DCMT 070204 7.70 6.35 2.38 0.40 2.80 • • • • • • 0.50-2.00 0.08-0.22

DCGT 11T302 11.60 9.52 3.97 0.20 4.40 • 0.50-2.00 0.08-0.20

DCGT 11T304 11.60 9.52 3.97 0.40 4.40 • • 1.00-2.50 0.12-0.25

DCMT 11T302 11.60 9.52 3.97 0.20 4.40 • • • • 0.50-2.00 0.08-0.20

DCMT 11T304 11.60 9.52 3.97 0.40 4.40 • • • 0.50-2.00 0.12-0.25

DCMT 11T308 11.60 9.52 3.97 0.80 4.40 • • • 1.50-3.00 0.14-0.29

• Right-hand inserts for right-hand external tools and for left-hand internal tools

(1) Right-hand insert

For tools, see page: CHA (760)

55° 107.5°

DCMT-PF 93º

55° Rhombic Inserts with a Positive di d1

Flank for Semi-Finishing and Finishing

on Soft Materials and Exotic Alloys 7°

r

l S

Recommended

Dimensions Tough 1 Hard

Machining Data

f

IC830 IC6025 IC8250 IC6015 IC806 IC807 IC907 ap (mm/

Designation l di S r d1 (mm) rev)

DCMT 070201-PF 7.70 6.35 2.38 0.10 2.80 • • 0.30-3.00 0.02-0.25

DCMT 070202-PF 7.70 6.35 2.38 0.20 2.80 • 0.40-3.00 0.03-0.25

DCMT 070204-PF 7.70 6.35 2.38 0.40 2.80 • 0.50-3.50 0.05-0.30

DCMT 070208-PF 7.70 6.35 2.38 0.80 2.80 • • 0.70-3.00 0.08-0.30

DCMT 11T302-PF 11.60 9.52 3.97 0.20 4.40 • • • • 0.30-2.50 0.04-0.25

DCMT 11T304-PF 11.60 9.52 3.97 0.40 4.40 • • • • • • • 0.50-3.00 0.05-0.25

DCMT 11T308-PF 11.60 9.52 3.97 0.80 4.40 • • • • • • • 0.70-3.00 0.10-0.25

For tools, see page: CHA (760)

107.5°

DCGT-AS 55˚ 7˚ 93° 62.5°

55° Rhombic Inserts with a 7° d

Positive Flank, Very Positive d1

Rake Angle and Sharp Cutting r 91° 93º

Edge for Machining Aluminum l S

Recommended

Dimensions Tough 1 Hard

Machining Data

IC920 IC907 ap f

Designation l di S r d1 IC20 (mm) (mm/rev)

DCGT 070201-AS 7.75 6.35 2.38 0.10 2.80 • 0.50-2.00 0.03-0.20

DCGT 070202-AS 7.75 6.35 2.38 0.20 2.80 • • 0.50-2.00 0.05-0.20

DCGT 070204-AS 7.75 6.35 2.38 0.40 2.80 • 0.50-2.50 0.05-0.25

DCGT 11T301-AS 11.60 9.52 3.97 0.10 4.40 • 0.50-2.50 0.05-0.25

DCGT 11T302-AS 11.60 9.52 3.97 0.20 4.40 • • 0.50-2.50 0.05-0.26

DCGT 11T304-AS 11.60 9.52 3.97 0.40 4.40 • • 0.50-2.50 0.05-0.25

DCGT 11T308-AS 11.60 9.52 3.97 0.80 4.40 • 0.80-3.00 0.08-0.30

For tools, see page: CHA (760)

805