Page 654 - Iscar

P. 654

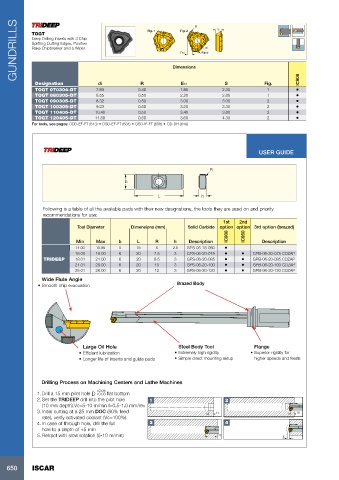

GUNDRILLS TOGT Fig. 1 Eh1 R Wiper S

Fig. 2

Deep Drilling Inserts with 3 Chip

Splitting Cutting Edges, Positive

Rake Chipbreaker and a Wiper

di

Designation di R Dimensions S Fig. IC908

Eh1

TOGT 070304-DT 7.69 0.40 1.95 2.30 1 •

TOGT 080305-DT 8.55 0.50 2.20 2.80 1 •

TOGT 090305-DT 8.32 0.50 3.00 3.00 2 •

TOGT 100305-DT 9.23 0.50 3.20 3.30 2 •

TOGT 110405-DT 10.40 0.50 3.40 3.80 2 •

TOGT 120405-DT 11.59 0.50 3.60 4.30 2 •

For tools, see pages: DDD-EF-FT (613) • DSD-EF-FT (604) • DSD-IF-FT (608) • GD-DH (649)

USER GUIDE

R

b

L h

Following is a table of all the available pads with their new designations, the tools they are used on and priority

recommendations for use:

1st 2nd

Tool Diameter Dimensions (mm) Solid Carbide option option 3rd option (brazed)

IC908 IC950

Min Max b L R h Description Description

14.00 15.99 5 18 6 2.5 GPS-05-18-060 •

16.00 18.00 6 20 7.5 3 GPS-06-20-075 • • GPB-06-20-075 CDZAP

TRIDEEP 18.01 21.00 6 20 8.5 3 GPS-06-20-085 • • GPB-06-20-085 CDZAP

21.01 25.00 6 20 10 3 GPS-06-20-100 • • GPB-06-20-100 CDZAP

25.01 28.00 6 20 12 3 GPS-06-20-120 • • GPB-06-20-120 CDZAP

Wide Flute Angle

• Smooth chip evacuation Brazed Body

Large Oil Hole Steel Body Tool Flange

• Efficient lubrication • Extremely high rigidity • Superior rigidity for

• Longer life of inserts and guide pads • Simple direct mounting setup higher speeds and feeds

Drilling Process on Machining Centers and Lathe Machines

+0.05

1. Drill a 15 mm pilot hole D +0.03 flat bottom

2. Set the TRIDEEP drill into the pilot hole 1 2

(10 mm depth).Vc=5-10 m/min f=0.5-1.0 mm/rev

3. Initial cutting at a 25 mm DOC (80% feed 15 10

rate), verify activated coolant (Vc=100%).

4. In case of through hole, drill the full 3 4

hole to a depth of +5 mm

5. Retract with slow rotation (5-10 m/min) 25 5

650 ISCAR