Page 546 - Iscar

P. 546

USER GUIDE

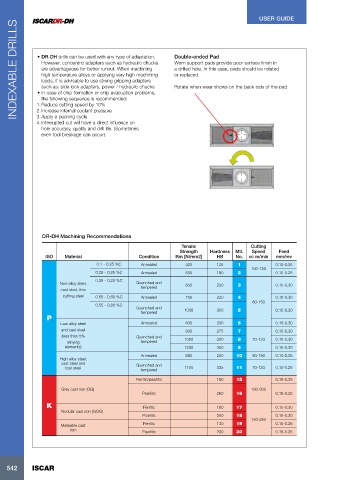

INDEXABLE DRILLS • DR-DH drills can be used with any type of adaptation. Double-ended Pad

However, concentric adapters such as hydraulic chucks

Worn support pads provide poor surface finish in

are advantageous for better runout. When machining

a drilled hole. In this case, pads should be rotated

or replaced.

high temperature alloys or applying very high machining

loads, it is advisable to use strong gripping adapters

such as: side lock adapters, power / hydraulic chucks

Rotate when wear shows on the back side of the pad

• In case of chip formation or chip evacuation problems,

the following sequence is recommended:

1. Reduce cutting speed by 10%

2. Increase internal coolant pressure

3. Apply a pecking cycle

4. Interrupted cut will have a direct influence on

hole accuracy, quality and drill life. (Sometimes

even tool breakage can occur).

DR-DH Machining Recommendations

Tensile Cutting

Strength Hardness Mtl. Speed Feed

ISO Material Condition Rm [N/mm2] HB No. vc m/min mm/rev

0.1 - 0.25 %C Annealed 420 125 1 0.10-0.25

100-150

0.25 - 0.25 %C Annealed 650 190 2 0.10-0.25

0.25 - 0.25 %C

Non-alloy steel, Quenched and 850 250 3 0.15-0.30

cast steel, free tempered

cutting steel 0.55 - 0.80 %C Annealed 750 220 4 0.15-0.30

80-150

0.55 - 0.80 %C

Quenched and 1000 300 5 0.15-0.30

tempered

P

Low alloy steel Annealed 600 200 6 0.15-0.30

and cast steel 930 275 7 0.15-0.30

(less than 5% Quenched and 1000 300 8 70-120 0.15-0.30

alloying tempered

elements) 1200 350 9 0.15-0.30

Annealed 680 200 10 80-150 0.10-0.25

High alloy steel,

cast steel and Quenched and

tool steel tempered 1100 325 11 70-120 0.10-0.25

Ferritic/pearlitic 180 15 0.18-0.35

Grey cast iron (GG) 180-300

Pearlitic 260 16 0.18-0.35

K Ferritic 160 17 0.15-0.30

Nodular cast iron (GGG)

Pearlitic 250 18 0.15-0.30

150-250

Ferritic 130 19 0.15-0.35

Malleable cast

iron Pearlitic 230 20 0.15-0.35

ISCAR

542 ISCAR

542