Page 26 - Iscar

P. 26

ENDMILLS • SOLID CARBIDE • MULTI-MASTER

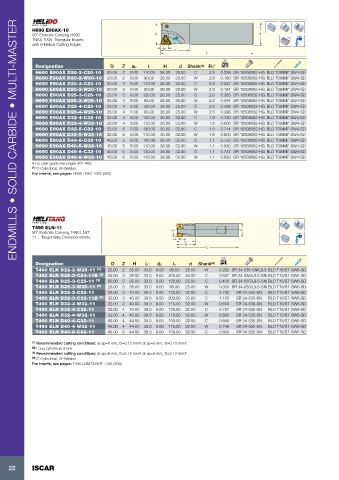

H690 E90AX-10

90° Endmills Carrying H690 D d

TNKX 1005..Triangular Inserts Rd°

with 6 Helical Cutting Edges

ap

H

L

Designation D Z ap L H d Shank (1) Rd° kg

H690 E90AX D20-2-C20-10 20.00 2 8.00 110.00 26.00 20.00 C 2.8 0.226 SR 10508082-HG BLD T08/M7 SW4-SD

H690 E90AX D20-2-W20-10 20.00 2 8.00 90.00 26.00 20.00 W 2.8 0.180 SR 10508082-HG BLD T08/M7 SW4-SD

H690 E90AX D20-3-C20-10 20.00 3 8.00 110.00 26.00 20.00 C 2.8 0.227 SR 10508082-HG BLD T08/M7 SW4-SD

H690 E90AX D20-3-W20-10 20.00 3 8.00 90.00 26.00 20.00 W 2.8 0.181 SR 10508082-HG BLD T08/M7 SW4-SD

H690 E90AX D25-3-C25-10 25.00 3 8.00 120.00 26.00 25.00 C 2.6 0.385 SR 10508082-HG BLD T08/M7 SW4-SD

H690 E90AX D25-3-W25-10 25.00 3 8.00 95.00 26.00 25.00 W 2.6 0.294 SR 10508082-HG BLD T08/M7 SW4-SD

H690 E90AX D25-4-C25-10 25.00 4 8.00 120.00 26.00 25.00 C 2.6 0.388 SR 10508082-HG BLD T08/M7 SW4-SD

H690 E90AX D25-4-W25-10 25.00 4 8.00 95.00 26.00 25.00 W 2.6 0.296 SR 10508082-HG BLD T08/M7 SW4-SD

H690 E90AX D32-4-C32-10 32.00 4 8.00 130.00 30.00 32.00 C 1.6 0.720 SR 10508082-HG BLD T08/M7 SW4-SD

H690 E90AX D32-4-W32-10 32.00 4 8.00 110.00 30.00 32.00 W 1.6 0.600 SR 10508082-HG BLD T08/M7 SW4-SD

H690 E90AX D32-5-C32-10 32.00 5 8.00 130.00 30.00 32.00 C 1.6 0.714 SR 10508082-HG BLD T08/M7 SW4-SD

H690 E90AX D32-5-W32-10 32.00 5 8.00 110.00 30.00 32.00 W 1.6 0.600 SR 10508082-HG BLD T08/M7 SW4-SD

H690 E90AX D40-5-C32-10 40.00 5 8.00 130.00 38.00 32.00 C 1.1 0.750 SR 10508082-HG BLD T08/M7 SW4-SD

H690 E90AX D40-5-W32-10 40.00 5 8.00 110.00 38.00 32.00 W 1.1 0.630 SR 10508082-HG BLD T08/M7 SW4-SD

H690 E90AX D40-6-C32-10 40.00 6 8.00 130.00 38.00 32.00 C 1.1 0.747 SR 10508082-HG BLD T08/M7 SW4-SD

H690 E90AX D40-6-W32-10 40.00 6 8.00 110.00 38.00 32.00 W 1.1 0.630 SR 10508082-HG BLD T08/M7 SW4-SD

• For user guide see pages 461-468

(1) C-Cylindrical, W-Weldon

For inserts, see pages: H690 TNKX 1005 (405)

T490 ELN-11 d

90° Endmills Carrying T490 LN#T D

11... Tangentially Clamped Inserts

ap

L1

H

L

Designation D Z H L1 ap L d Shank (4) kg

T490 ELN D22-2-W25-11 (1) 22.00 2 35.00 33.0 9.00 95.00 25.00 W 0.292 SR 34-535-SN/L9.3 BLD T15/S7 SW6-SD

T490 ELN D25-3-C24-11B (2) 25.00 3 35.00 33.0 9.00 200.00 24.00 C 0.637 SR 34-535/L9.5-SN BLD T15/S7 SW6-SD

T490 ELN D25-3-C25-11 (3) 25.00 3 35.00 33.0 9.00 120.00 25.00 C 0.400 SR 34-535/L9.5-SN BLD T15/S7 SW6-SD

T490 ELN D25-3-W25-11 (3) 25.00 3 35.00 33.0 9.00 95.00 25.00 W 0.300 SR 34-535/L9.5-SN BLD T15/S7 SW6-SD

T490 ELN D32-3-C32-11 32.00 3 40.00 38.0 9.00 130.00 32.00 C 0.730 SR 34-535-SN BLD T15/S7 SW6-SD

T490 ELN D32-3-C32-11B (2) 32.00 3 40.00 38.0 9.00 200.00 32.00 C 1.155 SR 34-535-SN BLD T15/S7 SW6-SD

T490 ELN D32-3-W32-11 32.00 3 40.00 38.0 9.00 110.00 32.00 W 0.600 SR 34-535-SN BLD T15/S7 SW6-SD

T490 ELN D32-4-C32-11 32.00 4 40.00 38.0 9.00 130.00 32.00 C 0.727 SR 34-535-SN BLD T15/S7 SW6-SD

T490 ELN D32-4-W32-11 32.00 4 40.00 38.0 9.00 110.00 32.00 W 0.660 SR 34-535-SN BLD T15/S7 SW6-SD

T490 ELN D40-4-C32-11 40.00 4 44.00 38.0 9.00 130.00 32.00 C 0.840 SR 34-535-SN BLD T15/S7 SW6-SD

T490 ELN D40-4-W32-11 40.00 4 44.00 38.0 9.00 115.00 32.00 W 0.746 SR 34-535-SN BLD T15/S7 SW6-SD

T490 ELN D40-5-C32-11 40.00 5 44.00 38.0 9.00 130.00 32.00 C 0.830 SR 34-535-SN BLD T15/S7 SW6-SD

(1) Recommended cutting conditions: at ap=6 mm, fz=0.12 mm/t at ap=8 mm, fz=0.10 mm/t

(2) Long cylindrical shank

(3) Recommended cutting conditions: at ap=6 mm, fz=0.15 mm/t at ap=8 mm, fz=0.12 mm/t

(4) C-Cylindrical, W-Weldon

For inserts, see pages: T490 LNMT/LNHT 1106 (408)

22 ISCAR