Page 170 - Iscar

P. 170

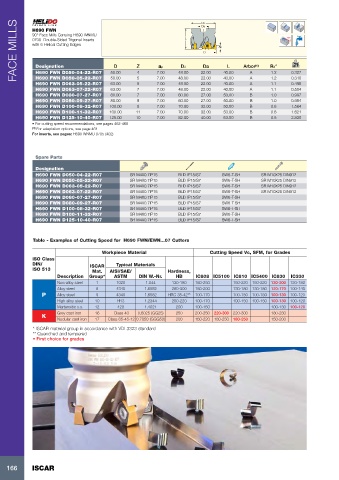

FACE MILLS H690 FWN D Z ap D3 L D3 D Da ap L Arbor (1) Rd° Rd° kg

Da

90° Face Mills Carrying H690 WNMU

0705 Double-Sided Trigonal Inserts

with 6 Helical Cutting Edges

Designation

H690 FWN D050-04-22-R07

40.00

H690 FWN D050-05-22-R07

7.00

50.00

22.00

48.00

0.310

1.2

H690 FWN D063-05-22-R07 50.00 4 5 5 7.00 48.00 22.00 40.00 A A A 1.2 0.327

63.00

48.00

7.00

40.00

22.00

1.1

0.498

H690 FWN D063-07-22-R07 63.00 7 7.00 48.00 22.00 40.00 A 1.1 0.504

H690 FWN D080-07-27-R07 80.00 7 7.00 60.00 27.00 50.00 B 1.0 0.997

H690 FWN D080-09-27-R07 80.00 9 7.00 60.00 27.00 50.00 B 1.0 0.984

H690 FWN D100-08-32-R07 100.00 8 7.00 70.00 32.00 50.00 B 0.8 1.564

H690 FWN D100-11-32-R07 100.00 11 7.00 70.00 32.00 50.00 B 0.8 1.621

H690 FWN D125-10-40-R07 125.00 10 7.00 82.00 40.00 63.00 B 0.5 2.830

• For cutting speed recommendations, see pages 462-468

(1) For adaptation options, see page 461

For inserts, see pages: H690 WNMU 0705 (402)

Spare Parts

Designation

H690 FWN D050-04-22-R07 SR M4X0.7IP15 BLD IP15/S7 SW6-T-SH SR M10X25 DIN912

H690 FWN D050-05-22-R07 SR M4X0.7IP15 BLD IP15/S7 SW6-T-SH SR M10X25 DIN912

H690 FWN D063-05-22-R07 SR M4X0.7IP15 BLD IP15/S7 SW6-T-SH SR M10X25 DIN912

H690 FWN D063-07-22-R07 SR M4X0.7IP15 BLD IP15/S7 SW6-T-SH SR M10X25 DIN912

H690 FWN D080-07-27-R07 SR M4X0.7IP15 BLD IP15/S7 SW6-T-SH

H690 FWN D080-09-27-R07 SR M4X0.7IP15 BLD IP15/S7 SW6-T-SH

H690 FWN D100-08-32-R07 SR M4X0.7IP15 BLD IP15/S7 SW6-T-SH

H690 FWN D100-11-32-R07 SR M4X0.7IP15 BLD IP15/S7 SW6-T-SH

H690 FWN D125-10-40-R07 SR M4X0.7IP15 BLD IP15/S7 SW6-T-SH

Table - Examples of Cutting Speed for H690 FWN/EWN...07 Cutters

Workpiece Material Cutting Speed Vc, SFM, for Grades

ISO Class

DIN/ ISCAR Typical Materials

ISO 513 Mat. AISI/SAE/ Hardness,

Description Group* ASTM DIN W.-Nr. HB IC808 IC5100 IC810 IC5400 IC830 IC330

Non-alloy steel 1 1020 1.044 130-180 180-250 150-220 150-220 130-200 120-180

Alloy steel 8 4340 1.6582 260-300 150-200 130-180 130-180 120-170 100-140

P Alloy steel 9 4340 1.6582 HRC 35-42** 100-170 100-150 100-150 100-130 100-120

High alloy steel 10 H13 1.2344 200-220 100-170 100-150 100-150 100-130 100-120

Martensitic s.s. 12 420 1.4021 200 100-150 100-130 100-120

K Grey cast iron 16 Class 40 0.6025 (GG25) 250 200-250 220-300 220-300 180-230

Nodular cast iron 17 Class 65-45-12 0.7050 (GGG50) 200 160-220 180-250 180-250 150-200

* ISCAR material group in accordance with VDI 3323 standard

** Quenched and tempered

• First choice for grades

166 ISCAR