Page 17 - Iscar

P. 17

T Ts

D

D3 Rd°

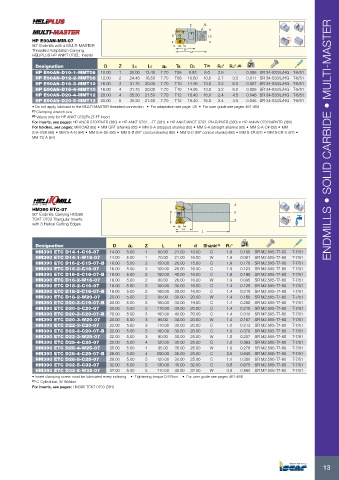

HP E90AN-MM-07

90° Endmills with a MULTI-MASTER ap

Threaded Adaptation Carrying L5 L6

HELIPLUS HP ANKT 0702.. Inserts

Designation D Z L6 L5 ap Ts D3 T (1) Rd° Rd°1 (2) kg

HP E90AN-D10-1-MMT06 10.00 1 20.00 13.40 7.70 T06 8.93 8.0 2.5 - 0.006 SR 34-533/L/HG T-6/51

HP E90AN-D12-2-MMT08 12.00 2 24.45 16.50 7.70 T08 10.60 10.0 2.7 3.5 0.011 SR 34-533/L/HG T-6/51

HP E90AN-D16-3-MMT10 16.00 3 31.75 20.00 7.70 T10 14.95 13.0 3.2 6.0 0.027 SR 34-533/L/HG T-6/51

HP E90AN-D16-4-MMT10 16.00 4 31.75 20.00 7.70 T10 14.95 13.0 3.2 6.0 0.026 SR 34-533/L/HG T-6/51

HP E90AN-D20-4-MMT12 20.00 4 35.30 21.50 7.70 T12 18.40 16.0 2.4 4.5 0.046 SR 34-533/L/HG T-6/51

HP E90AN-D20-5-MMT12 20.00 5 35.30 21.50 7.70 T12 18.40 16.0 2.4 4.5 0.046 SR 34-533/L/HG T-6/51

• Do not apply lubricant to the MULTI-MASTER threaded connection • For adaptation see page 38 • For user guide see pages 461-468

(1) Clamping wrench size

(2) Values only for HP ANKT 0702R12T-FF insert

For inserts, see pages: HP ANCR 0702PNFR (380) • HP ANKT 0702...-FF (381) • HP ANKT/ANCT 0702..PN-R/PNTR (380) • HP ANKW 070204PNTR (380)

For holders, see pages: MM CAB (69) • MM GRT (shanks) (65) • MM S-A (stepped shanks) (63) • MM S-A (straight shanks) (65) • MM S-A-C# (68) • MM

S-A-HSK (68) • MM S-A-N (64) • MM S-A-SK (68) • MM S-B (85° conical shanks) (65) • MM S-D (89° conical shanks) (66) • MM S-ER (67) • MM S-ER-H (67) •

MM TS-A (64) ENDMILLS • SOLID CARBIDE • MULTI-MASTER

HM390 ETC-07 D d

90° Endmills Carrying HM390

TCKT 0703 Triangular Inserts Rd°

with 3 Helical Cutting Edges

ap

H

L

Designation D ap Z L H d Shank (1) Rd° kg

HM390 ETC D14-1-C16-07 14.00 5.00 1 80.00 21.00 16.00 C 1.9 0.100 SR M2.5X5-T7-60 T-7/51

HM390 ETC D14-1-W16-07 14.00 5.00 1 70.00 21.00 16.00 W 1.9 0.081 SR M2.5X5-T7-60 T-7/51

HM390 ETC D16-2-C15-07-B 16.00 5.00 2 150.00 26.00 15.00 C 1.9 0.170 SR M2.5X5-T7-60 T-7/51

HM390 ETC D16-2-C16-07 16.00 5.00 2 100.00 26.00 16.00 C 1.9 0.123 SR M2.5X5-T7-60 T-7/51

HM390 ETC D16-2-C16-07-B 16.00 5.00 2 150.00 40.00 16.00 C 1.9 0.190 SR M2.5X5-T7-60 T-7/51

HM390 ETC D16-2-W16-07 16.00 5.00 2 80.00 26.00 16.00 W 1.9 0.095 SR M2.5X5-T7-60 T-7/51

HM390 ETC D18-2-C16-07 18.00 5.00 2 100.00 30.00 16.00 C 1.4 0.125 SR M2.5X5-T7-60 T-7/51

HM390 ETC D18-2-C16-07-B 18.00 5.00 2 160.00 30.00 16.00 C 1.4 0.210 SR M2.5X5-T7-60 T-7/51

HM390 ETC D18-2-W20-07 20.00 5.00 2 85.00 30.00 20.00 W 1.4 0.160 SR M2.5X5-T7-60 T-7/51

HM390 ETC D20-3-C19-07-B 20.00 5.00 3 160.00 30.00 19.00 C 1.4 0.280 SR M2.5X5-T7-60 T-7/51

HM390 ETC D20-3-C20-07 20.00 5.00 3 110.00 30.00 20.00 C 1.4 0.210 SR M2.5X5-T7-60 T-7/51

HM390 ETC D20-3-C20-07-B 20.00 5.00 3 160.00 40.00 20.00 C 1.4 0.310 SR M2.5X5-T7-60 T-7/51

HM390 ETC D20-3-W20-07 20.00 5.00 3 85.00 30.00 20.00 W 1.4 0.157 SR M2.5X5-T7-60 T-7/51

HM390 ETC D22-3-C20-07 22.00 5.00 3 110.00 30.00 20.00 C 1.0 0.213 SR M2.5X5-T7-60 T-7/51

HM390 ETC D22-3-C20-07-B 22.00 5.00 3 180.00 30.00 20.00 C 1.0 0.370 SR M2.5X5-T7-60 T-7/51

HM390 ETC D22-3-W25-07 22.00 5.00 3 90.00 30.00 25.00 W 1.0 0.257 SR M2.5X5-T7-60 T-7/51

HM390 ETC D25-4-C25-07 25.00 5.00 4 120.00 35.00 25.00 C 1.0 0.363 SR M2.5X6-T7-60 T-7/51

HM390 ETC D25-4-W25-07 25.00 5.00 4 95.00 35.00 25.00 W 1.0 0.278 SR M2.5X6-T7-60 T-7/51

HM390 ETC D28-4-C25-07-B 28.00 5.00 4 200.00 35.00 25.00 C 2.5 0.640 SR M2.5X6-T7-60 T-7/51

HM390 ETC D28-5-C25-07 28.00 5.00 5 120.00 30.00 25.00 C 1.0 0.380 SR M2.5X6-T7-60 T-7/51

HM390 ETC D32-5-C32-07 32.00 5.00 5 130.00 45.00 32.00 C 0.8 0.675 SR M2.5X6-T7-60 T-7/51

HM390 ETC D32-5-W32-07 32.00 5.00 5 110.00 45.00 32.00 W 0.8 0.560 SR M2.5X6-T7-60 T-7/51

• Insert clamping screw must be lubricated every indexing. • Tightening torque 0.9 Nxm. • For user guide see pages 461-468

(1) C-Cylindrical, W-Weldon

For inserts, see pages: HM390 TCKT 0703 (381)

13