Page 14 - Iscar

P. 14

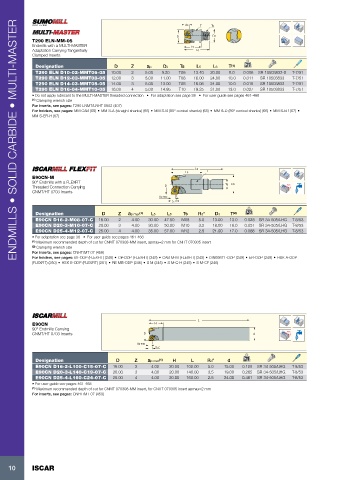

ENDMILLS • SOLID CARBIDE • MULTI-MASTER

ap T Ts

D D3

T290 ELN-MM-05

Endmills with a MULTI-MASTER L5

Adaptation Carrying Tangentially L6

Clamped Inserts

Designation D Z ap D3 Ts L5 L6 T (1) kg

T290 ELN D10-02-MMT06-05 10.00 2 5.00 9.20 T06 13.40 20.00 8.0 0.006 SR 10503833-S T-7/51

T290 ELN D12-03-MMT08-05 12.00 3 5.00 11.00 T08 16.00 24.00 10.0 0.011 SR 10503833 T-7/51

T290 ELN D14-03-MMT08-05 14.00 3 5.00 13.00 T08 16.06 24.00 10.0 0.015 SR 10503833 T-7/51

T290 ELN D16-04-MMT10-05 16.00 4 5.00 14.95 T10 19.25 31.00 13.0 0.027 SR 10503833 T-7/51

• Do not apply lubricant to the MULTI-MASTER threaded connection • For adaptation see page 38 • For user guide see pages 461-468

(1) Clamping wrench size

For inserts, see pages: T290 LNMT/LNHT 0502 (407)

For holders, see pages: MM CAB (69) • MM S-A (straight shanks) (65) • MM S-B (85° conical shanks) (65) • MM S-D (89° conical shanks) (66) • MM S-ER (67) •

MM S-ER-H (67)

L5 L6 T

E90CN-M

90° Endmills with a FLEXFIT Ts D3

Threaded Connection Carrying D Rd°

CNMT/HT 0703 Inserts

ap max

5.7

Designation D Z ap max (1) L5 L6 Ts Rd° D3 T (2) kg

E90CN D16-2-M08-07-C 16.00 2 4.00 30.00 47.50 M08 5.0 13.00 13.0 0.028 SR 34-505/LHG T-8/53

E90CN D20-3-M10-07-C 20.00 3 4.00 30.00 50.00 M10 3.5 18.00 16.0 0.051 SR 34-505/LHG T-8/53

E90CN D25-4-M12-07-C 25.00 4 4.00 35.00 57.00 M12 2.5 21.00 17.0 0.088 SR 34-505/LHG T-8/53

• For adaptation see page 38 • For user guide see pages 461-468

(1) Maximum recommended depth of cut for CNMT 070308-MM insert, apmax=2 mm for CNHT 070305 insert

(2) Clamping wrench size

For inserts, see pages: CNHT/MT 07 (459)

For holders, see pages: BT-ODP (FLEXFIT) (248) • C#-ODP (FLEXFIT) (248) • CAB M-M (FLEXFIT) (245) • DIN69871-ODP (249) • ER-ODP (249) • HSK A-ODP

(FLEXFIT) (250) • HSK E-ODP (FLEXFIT) (251) • RE MB-ODP (246) • S M (245) • S M-C-H (245) • S M-CF (246)

L

E90CN H

90° Endmills Carrying

CNMT/HT 0703 Inserts D d Rd°

ap max

5.7

Designation D Z ap max (1) H L Rd° d kg

E90CN D16-2-L100-C15-07-C 16.00 2 4.00 20.00 100.00 5.0 15.00 0.108 SR 34-505/LHG T-8/53

E90CN D20-3-L140-C19-07-C 20.00 3 4.00 20.00 140.00 3.5 19.00 0.265 SR 34-505/LHG T-8/53

E90CN D25-4-L160-C24-07-C 25.00 4 4.00 20.00 160.00 2.5 24.00 0.481 SR 34-505/LHG T-8/53

• For user guide see pages 461-468

(1) Maximum recommended depth of cut for CNMT 070308-MM insert, for CNHT 070305 insert apmax=2 mm

For inserts, see pages: CNHT/MT 07 (459)

10 ISCAR