Page 137 - Iscar

P. 137

r Rd°

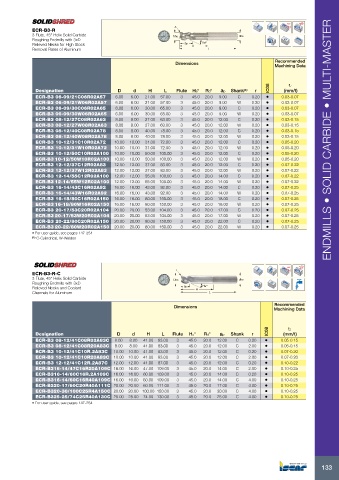

ECR-B3-R

3 Flute, 45° Helix Solid Carbide Dh6 dh6

Roughing Endmills with 3xD Haº

Relieved Necks for High Stock ap H

Removal Rates of Aluminum L

Recommended

Dimensions

Machining Data

IC08 fz

Designation D d H L Flute Ha° Rd° ap Shank (1) r (mm/t)

ECR-B3 06-09/21C06R02A57 6.00 6.00 21.00 57.00 3 45.0 20.0 9.00 C 0.20 • 0.03-0.07

ECR-B3 06-09/21W06R02A57 6.00 6.00 21.00 57.00 3 45.0 20.0 9.00 W 0.20 • 0.03-0.07

ECR-B3 06-09/30C06R02A65 6.00 6.00 30.00 65.00 3 45.0 20.0 9.00 C 0.20 • 0.03-0.07

ECR-B3 06-09/30W06R02A65 6.00 6.00 30.00 65.00 3 45.0 20.0 9.00 W 0.20 • 0.03-0.07

ECR-B3 08-12/27C08R02A63 8.00 8.00 27.00 63.00 3 45.0 20.0 12.00 C 0.20 • 0.03-0.15

ECR-B3 08-12/27W08R02A63 8.00 8.00 27.00 63.00 3 45.0 20.0 12.00 W 0.20 • 0.03-0.15

ECR-B3 08-12/40C08R02A78 8.00 8.00 40.00 78.00 3 45.0 20.0 12.00 C 0.20 • 0.03-0.15

ECR-B3 08-12/40W08R02A78 8.00 8.00 40.00 78.00 3 45.0 20.0 12.00 W 0.20 • 0.03-0.15

ECR-B3 10-12/31C10R02A72 10.00 10.00 31.00 72.00 3 45.0 20.0 12.00 C 0.20 • 0.05-0.20 ENDMILLS • SOLID CARBIDE • MULTI-MASTER

ECR-B3 10-12/31W10R02A72 10.00 10.00 31.00 72.00 3 45.0 20.0 12.00 W 0.20 • 0.05-0.20

ECR-B3 10-12/50C10R02A100 10.00 10.00 50.00 100.00 3 45.0 20.0 12.00 C 0.20 • 0.05-0.20

ECR-B3 10-12/50W10R02A100 10.00 10.00 50.00 100.00 3 45.0 20.0 12.00 W 0.20 • 0.05-0.20

ECR-B3 12-12/37C12R02A83 12.00 12.00 37.00 83.00 3 45.0 20.0 12.00 C 0.20 • 0.07-0.22

ECR-B3 12-12/37W12R02A83 12.00 12.00 37.00 83.00 3 45.0 20.0 12.00 W 0.20 • 0.07-0.22

ECR-B3 12-14/55C12R02A100 12.00 12.00 55.00 100.00 3 45.0 20.0 14.00 C 0.20 • 0.07-0.22

ECR-B3 12-14/55W12R02A100 12.00 12.00 55.00 100.00 3 45.0 20.0 14.00 W 0.20 • 0.07-0.22

ECR-B3 16-14/43C16R02A92 16.00 16.00 43.00 92.00 3 45.0 20.0 14.00 C 0.20 • 0.07-0.25

ECR-B3 16-14/43W16R02A92 16.00 16.00 43.00 92.00 3 45.0 20.0 14.00 W 0.20 • 0.07-0.25

ECR-B3 16-18/80C16R02A150 16.00 16.00 80.00 150.00 3 45.0 20.0 18.00 C 0.20 • 0.07-0.25

ECR-B3 16-18/80W16R02A150 16.00 16.00 80.00 150.00 3 45.0 20.0 18.00 W 0.20 • 0.07-0.25

ECR-B3 20-17/53C20R02A104 20.00 20.00 53.00 104.00 3 45.0 20.0 17.00 C 0.20 • 0.07-0.25

ECR-B3 20-17/53W20R02A104 20.00 20.00 53.00 104.00 3 45.0 20.0 17.00 W 0.20 • 0.07-0.25

ECR-B3 20-22/80C20R02A150 20.00 20.00 80.00 150.00 3 45.0 20.0 22.00 C 0.20 • 0.07-0.25

ECR-B3 20-22/80W20R02A150 20.00 20.00 80.00 150.00 3 45.0 20.0 22.00 W 0.20 • 0.07-0.25

• For user guide, see pages 147-254

(1) C-Cylindrical, W-Weldon

r Rd°

ECR-B3-R-C

3 Flute, 45° Helix Solid Carbide Dh6 dh6

Roughing Endmills with 3xD Haº

Relieved Necks and Coolant ap H

Channels for Aluminum L

Recommended

Dimensions Machining Data

IC08 fz

Designation D d H L Flute Ha° Rd° ap Shank r (mm/t)

ECR-B3 08-12/41C08R02A83C 8.00 8.00 41.00 83.00 3 45.0 20.0 12.00 C 0.20 • 0.05-0.15

ECR-B3 08-12/41C08R20A83C 8.00 8.00 41.00 83.00 3 45.0 20.0 12.00 C 2.00 • 0.05-0.15

ECR-B3 10-12/41C10R.2A83C 10.00 10.00 41.00 83.00 3 45.0 20.0 12.00 C 0.20 • 0.07-0.20

ECR-B3 10-12/41C10R20A83C 10.00 10.00 41.00 83.00 3 45.0 20.0 12.00 C 2.00 • 0.07-0.20

ECR-B3 12-12/41C12R.2A87C 12.00 12.00 41.00 87.00 3 45.0 20.0 12.00 C 0.20 • 0.10-0.22

ECR-B316-14/47C16R20A109C 16.00 16.00 47.00 109.00 3 45.0 20.0 14.00 C 2.00 • 0.10-0.25

ECR-B316-14/60C16R.2A109C 16.00 16.00 60.00 109.00 3 45.0 20.0 14.00 C 0.20 • 0.10-0.25

ECR-B316-14/60C16R40A109C 16.00 16.00 60.00 109.00 3 45.0 20.0 14.00 C 4.00 • 0.10-0.25

ECR-B320-17/60C20R40A111C 20.00 20.00 60.00 111.00 3 45.0 20.0 17.00 C 4.00 • 0.10-0.25

ECR-B320-30/100C25R4A150C 20.00 20.00 100.00 150.00 3 45.0 20.0 30.00 C 4.00 • 0.10-0.25

ECR-B325-25/74C25R40A130C 25.00 25.00 74.00 130.00 3 45.0 20.0 25.00 C 4.00 • 0.10-0.25

• For user guide, see pages 147-254

133