Page 48 - logic

P. 48

Engineered for

MAXIMUM

MULTI-MASTER

Performance

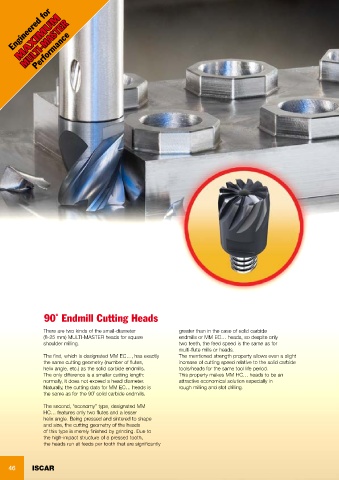

90˚ Endmill Cutting Heads

There are two kinds of the small-diameter greater than in the case of solid carbide

(8-25 mm) MULTI-MASTER heads for square endmills or MM EC… heads, so despite only

shoulder milling. two teeth, the feed speed is the same as for

multi-flute mills or heads.

The first, which is designated MM EC…, has exactly The mentioned strength property allows even a slight

the same cutting geometry (number of flutes, increase of cutting speed relative to the solid carbide

helix angle, etc.) as the solid carbide endmills. tools/heads for the same tool life period.

The only difference is a smaller cutting length: This property makes MM HC… heads to be an

normally, it does not exceed a head diameter. attractive economical solution especially in

Naturally, the cutting data for MM EC… heads is rough milling and slot drilling.

the same as for the 90˚ solid carbide endmills.

The second, “economy” type, designated MM

HC… features only two flutes and a lesser

helix angle. Being pressed and sintered to shape

and size, the cutting geometry of the heads

of this type is merely finished by grinding. Due to

the high-impact structure of a pressed tooth,

the heads run at feeds per tooth that are significantly

46 ISCAR