Page 60 - logic

P. 60

FOR INTERNAL USE ONL Y • SUBJECT TO CHANGE

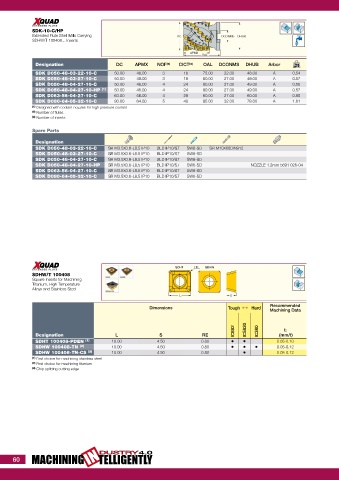

SDK-10-C/HP

Extended Flute Shell Mills Carrying DC DCONMS DHUB

SDHW/T 100408... Inserts

APMX

OAL

Designation DC APMX NOF (2) CICT (3) OAL DCONMS DHUB Arbor kg

SDK D050-48-03-22-10-C 50.00 48.00 3 18 75.00 22.00 48.00 A 0.54

SDK D050-48-03-27-10-C 50.00 48.00 3 18 80.00 27.00 49.00 A 0.57

SDK D050-48-04-27-10-C 50.00 48.00 4 24 80.00 27.00 49.00 A 0.56

SDK D050-48-04-27-10-HP (1) 50.00 48.00 4 24 80.00 27.00 49.00 A 0.57

SDK D063-56-04-27-10-C 63.00 56.00 4 28 80.00 27.00 60.00 A 0.90

SDK D080-64-05-32-10-C 80.00 64.00 5 40 85.00 32.00 78.00 A 1.61

(1) Designed with coolant nozzles for high pressure coolant

(2) Number of flutes

(3) Number of inserts

Spare Parts

Designation

SDK D050-48-03-22-10-C SR M3.5X0.6-L8.5 IP10 BLD IP10/S7 SW6-SD SR M10X60DIN912

SDK D050-48-03-27-10-C SR M3.5X0.6-L8.5 IP10 BLD IP10/S7 SW6-SD

SDK D050-48-04-27-10-C SR M3.5X0.6-L8.5 IP10 BLD IP10/S7 SW6-SD

SDK D050-48-04-27-10-HP SR M3.5X0.6-L8.5 IP10 BLD IP10/S7 SW6-SD NOZZLE 1.2mm 5691 026-04

SDK D063-56-04-27-10-C SR M3.5X0.6-L8.5 IP10 BLD IP10/S7 SW6-SD

SDK D080-64-05-32-10-C SR M3.5X0.6-L8.5 IP10 BLD IP10/S7 SW6-SD

SDHT RE SDHW

SDHW/T 100408

Square Inserts for Machining

Titanium, High Temperature

Alloys and Stainless Steel

L S

Recommended

Dimensions Tough 1 Hard Machining Data

IC882 IC5820 IC380 fz

Designation L S RE (mm/t)

SDHT 100408-PDEN (1) 10.00 4.50 0.80 • • 0.05-0.10

SDHW 100408-TN (2) 10.00 4.50 0.80 • • • 0.05-0.12

SDHW 100408-TN-CS (3) 10.00 4.50 0.80 • 0.05-0.12

(1) First choice for machining stainless steel

(2) First choice for machining titanium

(3) Chip splitting cutting edge

DUSTRY 4.0

MACHINING IN TELLIGENTLY

60