Page 44 - logic

P. 44

FOR INTERNAL USE ONL Y • SUBJECT TO CHANGE

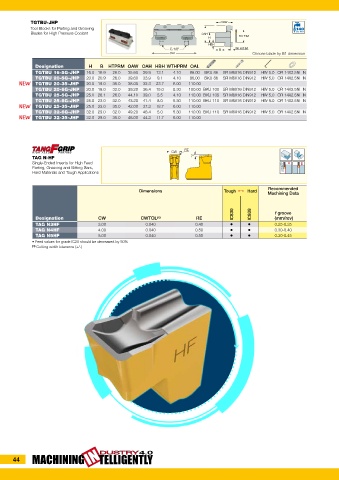

TGTBU-JHP OAW

Tool Blocks for Parting and Grooving

Blades for High Pressure Coolant OAH Bar Max

H HTPRM

HBH

G 1/8" B WTHPRM

OAL Choose blade by B1 dimension

Designation H B HTPRM OAW OAH HBH WTHPRM OAL

TGTBU 16-5G-JHP 16.0 16.9 26.0 35.60 29.9 13.1 4.10 86.00 BKU 86 SR M6X16 DIN912 HW 5.0 OR 14X2.5N N

TGTBU 20-5G-JHP 20.0 20.9 26.0 39.60 33.9 9.1 4.10 86.00 BKU 86 SR M6X16 DIN912 HW 5.0 OR 14X2.5N N

NEW TGTBU 20-35-JHP 20.0 19.0 35.0 38.00 32.3 23.7 6.00 110.00

TGTBU 20-6G-JHP 20.0 19.0 32.0 39.20 36.4 15.0 5.30 100.00 BKU 100 SR M6X16 DIN912 HW 5.0 OR 14X2.5N N

TGTBU 25-5G-JHP 25.0 26.1 26.0 44.10 39.0 5.5 4.10 110.00 BKU 105 SR M6X16 DIN912 HW 5.0 OR 14X2.5N N

TGTBU 25-6G-JHP 25.0 23.0 32.0 43.20 41.4 8.0 5.30 110.00 BKU 110 SR M6X16 DIN912 HW 5.0 OR 14X2.5N N

NEW TGTBU 25-35-JHP 25.0 23.0 35.0 42.00 37.3 18.7 6.00 110.00

TGTBU 32-6G-JHP 32.0 29.0 32.0 49.20 48.4 5.0 5.30 110.00 BKU 110 SR M6X16 DIN912 HW 5.0 OR 14X2.5N N

NEW TGTBU 32-35-JHP 32.0 29.0 35.0 48.00 44.3 11.7 6.00 110.00

CW RE

TAG N-HF 7°

Single-Ended Inserts for High Feed

Parting, Grooving and Slitting Bars,

Hard Materials and Tough Applications

Recommended

Dimensions Tough 1 Hard Machining Data

IC830 IC808 f groove

Designation CW CWTOL (1) RE (mm/rev)

TAG N3HF 3.00 0.040 0.40 • • 0.25-0.35

TAG N4HF 4.00 0.040 0.50 • • 0.30-0.40

TAG N5HF 5.00 0.040 0.50 • • 0.30-0.45

• Feed values for grade IC20 should be decreased by 50%

(1) Cutting width tolerance (+/-)

TELLIGENTLY

MACHINING IN DUSTRY 4.0

44