Page 888 - Iscar

P. 888

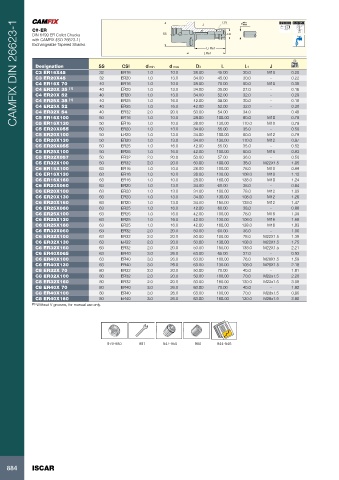

CAMFIX DIN 26623-1

J CSI d max A 0.003 A 58-60 HRc

min

C#-ER

DIN 6499 ER Collet Chucks SS D3

with CAMFIX (ISO 26623-1)

Exchangeable Tapered Shanks

L1 Ref

L Ref

Designation SS CSI d min d max D3 L L1 J kg

C3 ER16X45 32 ER16 1.0 10.0 28.00 45.00 30.0 M10 0.20

C3 ER20X45 32 ER20 1.0 13.0 34.00 45.00 30.0 - 0.22

C4 ER16X 70 40 ER16 1.0 10.0 28.00 70.00 50.0 M10 0.38

C4 ER20X 35 (1) 40 ER20 1.0 13.0 34.00 35.00 27.0 - 0.16

C4 ER20X 52 40 ER20 1.0 13.0 34.00 52.00 32.0 - 0.29

C4 ER25X 38 (1) 40 ER25 1.0 16.0 42.00 38.00 30.0 - 0.18

C4 ER25X 52 40 ER25 1.0 16.0 42.00 52.00 32.0 - 0.30

C4 ER32X 54 40 ER32 2.0 20.0 50.00 54.00 34.0 - 0.48

C5 ER16X100 50 ER16 1.0 10.0 28.00 100.00 80.0 M10 0.78

C5 ER16X130 50 ER16 1.0 10.0 28.00 130.00 110.0 M10 0.79

C5 ER20X055 50 ER20 1.0 13.0 34.00 55.00 35.0 - 0.50

C5 ER20X100 50 ER20 1.0 13.0 34.00 100.00 80.0 M12 0.79

C5 ER20X130 50 ER20 1.0 13.0 34.00 130.00 110.0 M12 0.97

C5 ER25X055 50 ER25 1.0 16.0 42.00 55.00 35.0 - 0.52

C5 ER25X100 50 ER25 1.0 16.0 42.00 100.00 80.0 M16 0.93

C5 ER32X057 50 ER32 2.0 20.0 50.00 57.00 36.0 - 0.50

C5 ER32X100 50 ER32 2.0 20.0 50.00 100.00 36.0 M22X1.5 1.05

C6 ER16X100 63 ER16 1.0 10.0 28.00 100.00 78.0 M10 0.99

C6 ER16X130 63 ER16 1.0 10.0 28.00 130.00 108.0 M10 1.12

C6 ER16X160 63 ER16 1.0 10.0 28.00 160.00 138.0 M10 1.24

C6 ER20X060 63 ER20 1.0 13.0 34.00 60.00 38.0 - 0.84

C6 ER20X100 63 ER20 1.0 13.0 34.00 100.00 78.0 M12 1.09

C6 ER20X130 63 ER20 1.0 13.0 34.00 130.00 108.0 M12 1.26

C6 ER20X160 63 ER20 1.0 13.0 34.00 160.00 138.0 M12 1.47

C6 ER25X060 63 ER25 1.0 16.0 42.00 60.00 38.0 - 0.86

C6 ER25X100 63 ER25 1.0 16.0 42.00 100.00 78.0 M16 1.39

C6 ER25X130 63 ER25 1.0 16.0 42.00 130.00 108.0 M16 1.68

C6 ER25X160 63 ER25 1.0 16.0 42.00 160.00 138.0 M16 1.83

C6 ER32X060 63 ER32 2.0 20.0 50.00 60.00 36.0 - 1.06

C6 ER32X100 63 ER32 2.0 20.0 50.00 100.00 78.0 M22X1.5 1.38

C6 ER32X130 63 ER32 2.0 20.0 50.00 130.00 108.0 M22X1.5 1.75

C6 ER32X160 63 ER32 2.0 20.0 50.00 160.00 138.0 M22X1.5 2.21

C6 ER40X065 63 ER40 3.0 26.0 63.00 65.00 37.0 - 0.93

C6 ER40X100 63 ER40 3.0 26.0 63.00 100.00 78.0 M28X1.5 1.59

C6 ER40X130 63 ER40 3.0 26.0 63.00 130.00 108.0 M28X1.5 2.18

C8 ER32X 70 80 ER32 2.0 20.0 50.00 70.00 40.0 - 1.81

C8 ER32X100 80 ER32 2.0 20.0 50.00 100.00 70.0 M22x1.5 2.20

C8 ER32X160 80 ER32 2.0 20.0 50.00 160.00 130.0 M22x1.5 3.08

C8 ER40X 70 80 ER40 3.0 26.0 63.00 70.00 40.0 - 1.82

C8 ER40X100 80 ER40 3.0 26.0 63.00 100.00 70.0 M28x1.5 0.86

C8 ER40X160 80 ER40 3.0 26.0 63.00 160.00 130.0 M28x1.5 3.80

(1) Without V grooves, for manual use only.

979-980 981 947-950 980 944-946

C

l8 A

CAMFIX ISO 26623-1 l7 2e

d4

Toolholder Standard d2 d1 Dm

d5 b2

l1

l11 A

l6 A-A C-C

l2 l3

C

CAMFIX b2 d1 ±0.1 d2 d4 d5 ±0.1 Dm e l1 l2 ±0.1 l3 min l6 ±0.15 l7 ±0.15 l8 min l11 ±0.1

C3 28,3 32 15 M12x1.5 3,6 22 0,7 2,5 19 15 6 13 25 8

C4 35,3 40 18 M14x1.5 4,6 28 0,9 2,5 24 20 8 15 30 11,5

C5 44,4 50 21 M16x1.5 6,1 35 1,12 3 30 20 10 20 37 14

C6 55,8 63 28 M20x2 8,1 44 1,4 3 38 22 12 27 47 15,5

C8 71,1 80 32 M20x2 9,1 55 2 3 48 30 12 28 48 25

C8X 88,7 100 32 M20x2 9,1 55 2 3 48 32 16 28 48 25

CAMFIX - ISO 26623-1

Standard Quick Change Alignment point of the toolholder with extensions

ISCAR

884 Shanks Coolant (for modular systems)

technologic hole

V-groove for ATC

Magazine (Automatic Tool Change) arm

and spindle

positioning groove

Features

• Symmetrical design: Due to the symmetrical design,

the torque load is distributed on the polygon, providing a self-centering effect.

• Rigidity: The CAMFIX clamping mechanism is extremely rigid against bending forces.

• Accuracy: The taper and face contact ensure high repeatability within 2 microns,

when operated with an automatic tool changer.