Page 881 - Iscar

P. 881

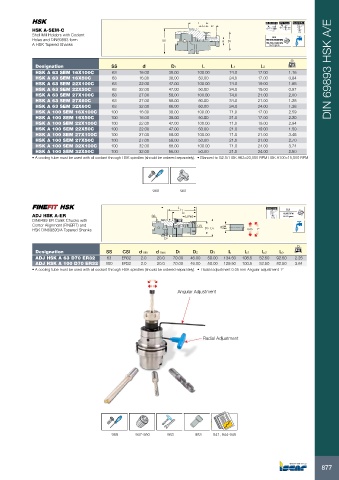

L L1 A 0.005 A AT3 Taper 58-60 HRc

HSK A-SEM-C L2

Shell Mill Holders with Coolant G2.5

Holes and DIN69893 form SS d D1 HSK A 63=20,000 RPM

A HSK Tapered Shanks HSK A100=15,000 RPM

U<1.0 gmm

Designation SS d D1 L L1 L2 kg

HSK A 63 SEM 16X100C 63 16.00 38.00 100.00 74.0 17.00 1.16 DIN 69893 HSK A/E

HSK A 63 SEM 16X50C 63 16.00 38.00 50.00 24.0 17.00 0.84

HSK A 63 SEM 22X100C 63 22.00 47.00 100.00 74.0 19.00 1.68

HSK A 63 SEM 22X50C 63 22.00 47.00 50.00 24.0 19.00 0.97

HSK A 63 SEM 27X100C 63 27.00 58.00 100.00 74.0 21.00 2.00

HSK A 63 SEM 27X60C 63 27.00 58.00 60.00 34.0 21.00 1.28

HSK A 63 SEM 32X60C 63 32.00 66.00 60.00 34.0 24.00 1.38

HSK A 100 SEM 16X100C 100 16.00 38.00 100.00 71.0 17.00 2.59

HSK A 100 SEM 16X50C 100 16.00 38.00 50.00 21.0 17.00 2.20

HSK A 100 SEM 22X100C 100 22.00 47.00 100.00 71.0 19.00 2.94

HSK A 100 SEM 22X50C 100 22.00 47.00 50.00 21.0 19.00 1.50

HSK A 100 SEM 27X100C 100 27.00 58.00 100.00 71.0 21.00 3.46

HSK A 100 SEM 27X50C 100 27.00 58.00 50.00 21.0 21.00 2.70

HSK A 100 SEM 32X100C 100 32.00 66.00 100.00 71.0 24.00 3.74

HSK A 100 SEM 32X50C 100 32.00 66.00 50.00 21.0 24.00 2.60

• A cooling tube must be used with all coolant through HSK spindles (should be ordered separately). • Blanced to G2.5/ HSK A63=20,000 RPM HSK A100=15,000 RPM

HSK A-SEM-C 989 981

Advantages

• Prolonged insert life (especially when milling titanium and aluminum)

• Symmetrical design – may be used at high RPM L L1 58-60 HRc G2.5

• Heavy duty driving keys for higher torque transfer

ADJ HSK A-ER SS L5 L3 Ref. 15,000 RPM

U<1.0 gmm

• Dramatically improved chip evacuation

DIN6499 ER Collet Chucks with

• Improved surface finish

Center Alignment (FINEFIT) and CSI d min

HSK DIN69893/A Tapered Shanks D3 D1 max 0.05 1°

D2

Heavy duty driving kg

CSI

Designation SS keys for higher torque D1 D2 D3 L L1 L3 L5

d min

d max

ADJ HSK A 63 D70 ER32 63 ER32 2.0 20.0 70.00 46.00 50.00 134.50 108.5 52.50 92.50 2.25

ADJ HSK A 100 D70 ER32 100 ER32 2.0 20.0 70.00 46.00 50.00 129.50 100.5 52.50 82.50 3.64

• A cooling tube must be used with all coolant through HSK spindles (should be ordered separately). • Radial adjustment 0.05 mm Angular adjustment 1°

4 coolant outlets at 90°

from each other on the Angular Adjustment

spigot diameter

4 coolant outlets located on the

spigot, 90˚ from each other

Radial Adjustment

989 947-950 983 983 841, 944-946

877