Page 870 - Iscar

P. 870

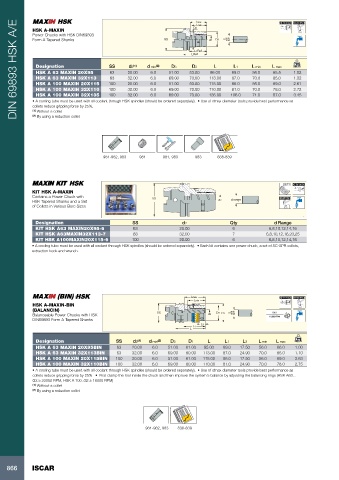

DIN 69893 HSK A/E HSK A-MAXIN 100 20.00 d min (2) SS 51.00 53.00 d2 95.00 d min 106.0 L min L max A 0.003 A 58-60 HRc

Lmax

Lmin

D2

Power Chucks with HSK DIN69893

Form A Tapered Shanks

D3

max

L1Ref.

LRef.

kg

SS

L

Designation

(1)

D2

L1

d2

D3

HSK A 63 MAXIN 20X95

1.02

69.0

63

6.0

56.0

65.5

69.00

70.00

1.32

63

32.00

6.0

70.0

87.0

113.00

85.0

HSK A 63 MAXIN 32X113

2.61

20.00

86.0

56.0

69.0

53.00

51.00

115.00

6.0

HSK A 100 MAXIN 20X115

6.0

81.0

70.0

69.00

110.00

70.00

HSK A 100 MAXIN 32X110

78.0

100

32.00

2.72

135.00

69.00

3.45

70.00

100

HSK A 100 MAXIN 32X135

6.0

32.00

71.0

87.0

• A cooling tube must be used with all coolant through HSK spindles (should be ordered separately). • Use of dmax diameter tools provide best performance as

collets reduce gripping force by 25%.

(1) Without a collet

(2) By using a reduction collet

961-962, 983 981 981, 983 983 838-839

SETS A 0.003 A

KIT HSK A-MAXIN

Contains a Power Chuck with SS 58-60 HRc

HSK Tapered Shanks and a Set d2 d range

of Collets in Various Bore Sizes

.

Designation SS d2 Qty d Range

KIT HSK A63 MAXIN20X95-6 63 20.00 6 6,8,10,12,14,16

KIT HSK A63MAXIN32X113-7 63 32.00 7 6,8,10,12,16,20,25

KIT HSK A100MAXIN20X115-6 100 20.00 6 6,8,10,12,14,16

• A cooling tube must be used with all coolant through HSK spindles (should be ordered separately). • Each kit contains one power chuck, a set of SC-SPR collets,

extraction hook and wrench.

Lmax A 0.003 A 58-60 HRc

Lmin

HSK A-MAXIN-BIN

(BALANCIN) SS d min

G6.3

Balanceable Power Chucks with HSK d2 D3 D1 max 10,000 RPM

DIN69893 Form A Tapered Shanks

L3

L1

L

Designation SS d2 (1) d min (2) D3 D1 L L1 L3 L min L max kg

HSK A 63 MAXIN 20X95BIN 63 20.00 6.0 51.00 61.00 95.00 69.0 17.50 56.0 66.0 1.00

HSK A 63 MAXIN 32X113BIN 63 32.00 6.0 69.00 80.00 113.00 87.0 24.90 70.0 85.0 1.10

HSK A 100 MAXIN 20X115BIN 100 20.00 6.0 51.00 61.00 115.00 86.0 17.50 56.0 69.0 2.63

HSK A 100 MAXIN 32X110BIN 100 32.00 6.0 69.00 80.00 110.00 81.0 24.90 70.0 78.0 2.75

• A cooling tube must be used with all coolant through HSK spindles (should be ordered separately). • Use of dmax diameter tools provide best performance as

collets reduce gripping force by 25% • First clamp the tool inside the chuck and then improve the system's balance by adjusting the balancing rings (HSK A63...

G2.5 20000 RPM, HSK A 100..G2.5 18000 RPM)

(1) Without a collet

(2) By using a reduction collet

961-962, 983 836-839

866 ISCAR