Page 758 - Iscar

P. 758

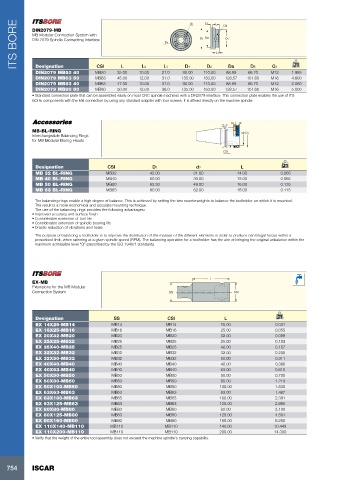

DIN2079-MB G1 L3 L CSI

ITS BORE MB Modular Connection System with D5 D2 Da L1 D1

DIN 2079 Spindle Connecting Interface

kg

L

Da

Designation

CSI

D2

D1

L3

L1

D5

G1

DIN2079 MB50 40 MB50 35.00 10.00 21.0 90.00 110.00 88.89 66.70 M12 1.955

DIN2079 MB63 50 MB63 45.00 12.00 31.0 135.00 150.00 128.57 101.60 M16 4.600

DIN2079 MB63 40 MB63 47.00 10.00 31.0 90.00 110.00 88.89 66.70 M12 2.060

DIN2079 MB80 50 MB80 50.00 12.00 36.0 135.00 150.00 128.57 101.60 M16 5.000

• Standard connection plate that can be assembled easily on most CNC spindle machines with a DIN2079 interface. This connection plate enables the use of ITS

BORE components with the MB connection by using any standard adapter with four screws. It is affixed directly on the machine spindle.

60° L

MB-BL-RING 30° 0 1 2 g6 d2 D1

Interchangeable Balancing Rings

for MB Modular Boring Heads

CSI

Designation CSI D1 d2 L kg

MB 32 BL-RING MB32 42.00 31.00 14.00 0.065

MB 40 BL-RING MB40 50.00 39.00 15.00 0.065

MB 50 BL-RING MB50 63.50 49.00 16.00 0.135

MB 63 BL-RING MB63 80.00 62.00 18.00 0.115

The balancing rings enable a high degree of balance. This is achieved by setting the two counterweights to balance the toolholder on which it is mounted.

The result is a more economical and accurate mounting technique.

The use of the balancing rings provides the following advantages:

• Improved accuracy and surface finish

• Considerable extension of tool life

• Considerable extension of spindle bearing life

• Drastic reduction of vibrations and noise

The purpose of balancing a toolholder is to improve the distribution of the masses of the different elements in order to produce centrifugal forces within a

prescribed limit, when spinning at a given spindle speed (RPM). The balancing operation for a toolholder has the aim of bringing the original unbalance within the

maximum admissible level “G” prescribed by the ISO 1940/1 standards.

EX-MB L

Extensions for the MB Modular

Connection System SS CSI

Designation SS CSI L kg

EX 14X25-MB14 MB14 MB14 25.00 0.041

EX 16X25-MB16 MB16 MB16 25.00 0.055

EX 20X32-MB20 MB20 MB20 32.00 0.088

EX 25X25-MB25 MB25 MB25 25.00 0.103

EX 25X40-MB25 MB25 MB25 40.00 0.157

EX 32X32-MB32 MB32 MB32 32.00 0.205

EX 32X50-MB32 MB32 MB32 50.00 0.311

EX 40X40-MB40 MB40 MB40 40.00 0.386

EX 40X63-MB40 MB40 MB40 63.00 0.610

EX 50X50-MB50 MB50 MB50 50.00 0.700

EX 50X80-MB50 MB50 MB50 80.00 1.210

EX 50X100-MB50 MB50 MB50 100.00 1.530

EX 63X63-MB63 MB63 MB63 63.00 1.487

EX 63X100-MB63 MB63 MB63 100.00 2.391

EX 63X125-MB63 MB63 MB63 125.00 2.990

EX 80X80-MB80 MB80 MB80 80.00 3.100

EX 80X125-MB80 MB80 MB80 125.00 4.501

EX 80X160-MB80 MB80 MB80 160.00 6.250

EX 110X140-MB110 MB110 MB110 140.00 10.449

EX 110X200-MB110 MB110 MB110 200.00 14.300

• Verify that the weight of the entire tool assembly does not exceed the machine spindle's carrying capability.

754 ISCAR