Page 757 - Iscar

P. 757

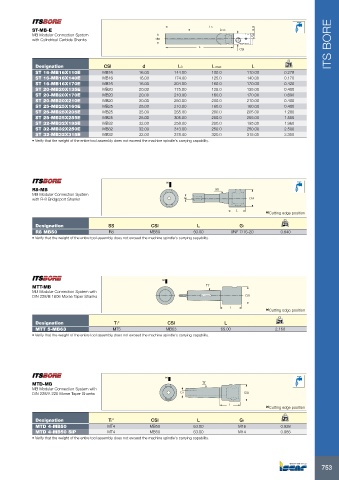

L3

ST-MB-E Lmax

MB Modular Connection System

with Cylindrical Carbide Shanks dh6

L ITS BORE

CSI

Designation CSI d L3 L max L kg

ST 16-MB16X110E MB16 16.00 144.00 100.0 110.00 0.278

ST 16-MB16X140E MB16 16.00 174.00 125.0 140.00 0.170

ST 16-MB16X170E MB16 16.00 204.00 160.0 170.00 0.420

ST 20-MB20X135E MB20 20.00 175.00 125.0 135.00 0.400

ST 20-MB20X170E MB20 20.00 210.00 160.0 170.00 0.690

ST 20-MB20X210E MB20 20.00 250.00 200.0 210.00 0.400

ST 25-MB25X160E MB25 25.00 210.00 160.0 160.00 0.400

ST 25-MB25X205E MB25 25.00 255.00 200.0 205.00 1.280

ST 25-MB25X255E MB25 25.00 305.00 250.0 255.00 1.555

ST 32-MB32X195E MB32 32.00 258.00 200.0 195.00 1.960

ST 32-MB32X250E MB32 32.00 313.00 250.0 250.00 2.500

ST 32-MB32X315E MB32 32.00 378.00 320.0 315.00 3.300

• Verify that the weight of the entire tool assembly does not exceed the machine spindle's carrying capability.

(a)

R8-MB SS

MB Modular Connection System

with R-8 Bridgeport Shanks G1 CSI

L

(a) Cutting edge position

Designation SS CSI L G1 kg

R8 MB50 R8 MB50 50.00 UNF 7/16-20 0.840

• Verify that the weight of the entire tool assembly does not exceed the machine spindle's carrying capability.

(a)

MTT-MB Tt˚

MB Modular Connection System with

DIN 228/B 1806 Morse Taper Shanks CSI

L

(a) Cutting edge position

Designation Tt° CSI L kg

MTT 5-MB63 MT5 MB63 65.00 2.160

• Verify that the weight of the entire tool assembly does not exceed the machine spindle's carrying capability.

(a)

MTD-MB Tt˚

MB Modular Connection System with

DIN 228/A 220 Morse Taper Shanks G1 CSI

L

(a) Cutting edge position

Designation Tt° CSI L G1 kg

MTD 4-MB50 MT4 MB50 63.00 M16 0.928

MTD 4-MB50 SIP MT4 MB50 63.00 M14 0.985

• Verify that the weight of the entire tool assembly does not exceed the machine spindle's carrying capability.

753