Page 721 - Iscar

P. 721

USER GUIDE

TAPS

Tap Surface Treatments and Coating Types

The high speed steels we use grant high wear resistance TiAIN-COATING – TiAIN

and toughness.

For machining certain materials, various surface This is a special coating for machining abrasive materials

treatments are an advantage. such as: grey cast iron, alu-alloys with silicon, fiber

reinforced plastics, etc., or machining under high

Steam Tempered (ST) temperatures, which means with insufficient cooling, or

The steam tempered is a Fe O oxide coating which high speeds ≥ 600m/min. The TiAIN has a hardness of

4

3

reduces the friction between the tool and workpiece and approx. 3,000 HV and is temperature resistant up to

prevents cold welding. approx. 800°.

Color: Violet-grey coefficient of friction against steel : 0.4

Nitriding (NI)

Hardslick-COATING – Hardslick

Recommended surface treatment for machining hard

wear/abrasive materials such as grey cast iron, Hardslick combines in a novel way the advantages of an

extremely hard, thermally stable TiAIN-coating with the

aluminum alloys with high silicon percentage (more

than 10%). sliding and lubricating properties of an outer

WC/C (Tungsten carbide/carbon) coating. The hardslick

TiN Coating (TI) coating has a hardness of approx. 3,000 HV and is

temperature-resistant up to approx. 800°.

The TiN coating has a hardness of approximately 2,300

HV and is temperature resistant up to approximately Color: Violet-grey coefficient of friction against steel : 0.2

600°C. This is an excellent golden colored coating Tolerances According to DIN EN 22857

for general applications.

For taps with ISO metric threads.

TiCN-COATING – TiCN

The following chart gives a comparison between

TiCN takes place of TiN when the conditions require the

coating to have a different the new standard DIN EN 22857 and the withdrawn

hardness and toughness. standard DIN 802 part 1. An important change is

The TiCN brings an advantage to machining very difficult the re-classification from tap tolerance to tap

steels or cutting application class.

interrupted bores.

The TiCN-coating has a hardness of approx. 3,000 HV,

but is temperature-resistant up to approx. 400° only. That

means TiCN needs excellent cooling for long service life.

Color: Blue-grey coefficient of friction against steel : 0.4

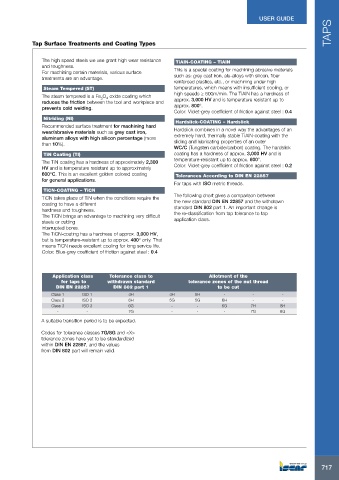

Application class Tolerance class to Allotment of the

for taps to withdrawn standard tolerance zones of the nut thread

DIN EN 22857 DIN 802 part 1 to be cut

Class 1 ISO 1 4H 4H 5H - - -

Class 2 ISO 2 6H 5G 5G 6H - -

Class 3 ISO 3 6G - - 6G 7H 8H

- - 7G - - - 7G 8G

A suitable transition period is to be expected.

Codes for tolerance classes 7G/8G and <X>

tolerance zones have yet to be standardized

within DIN EN 22857, and the values

from DIN 802 part will remain valid.

717

717