Page 471 - Iscar

P. 471

USER GUIDE

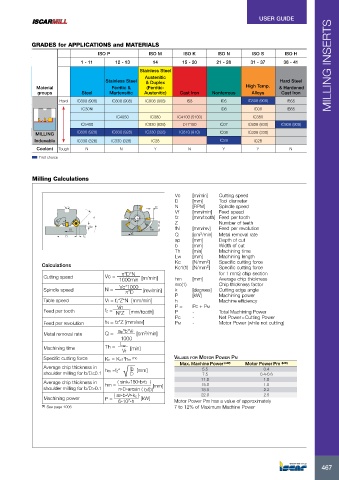

GRADES for APPLICATIONS and MATERIALS

ISO P ISO M ISO K ISO N ISO S ISO H

1 - 11 12 - 13 14 15 - 20 21 - 28 31 - 37 38 - 41 MILLING INSERTS

Stainless Steel

Austenitic

Stainless Steel & Duplex Hard Steel

Material Ferritic & (Ferritic- High Temp. & Hardened

groups Steel Martensitic Austenitic) Cast Iron Nonferrous Alloys Cast Iron

Hard IC808 (908) IC808 (908) IC808 (908) IS8 ID5 IC808 (908) IB55

IC30N ID8 IC08 IB85

IC4050 IC380 IC4100 (5100) IC380

IC5400 IC830 (928) DT7150 IC07 IC928 (830) IC808 (908)

MILLING IC830 (928) IC830 (928) IC330 (328) IC810 (910) IC08 IC328 (330)

Indexable IC330 (328) IC330 (328) IC28 IC28 IC28

Coolant Tough N N Y N Y Y N

First choice

Milling Calculations

Vc [m/min] Cutting speed

D [mm] Tool diameter

N fz N [RPM] Spindle speed

Vf [mm/min] Feed speed

κ fz [mm/tooth] Feed per tooth

N n

b Z Number of teeth

ap fN [mm/rev] Feed per revolution

Vf hm

Vf Q [cm /min] Metal removal rate

3

D fz

ap [mm] Depth of cut

b [mm] Width of cut

Th [min] Machining time

Lw [mm] Machining length

2

Kc [N/mm ] Specific cutting force

Calculations Kc1(1) [N/mm ] Specific cutting force

2

Cutting speed Vc = π*D*N [m/min] hm [mm] for 1 mm2 chip section

Average chip thickness

1000min mc(1) Chip thickness factor

Spindle speed N = Vc*1000 [rev/min] k [degrees] Cutting edge angle

π*D

P [kW] Machining power

Table speed Vf = fz*Z*N [mm/min] h Machine efficiency

Vn P = Pc + Pm

Feed per tooth fz = N*Z [mm/tooth] P - Total Machining Power

Pc - Net Power=Cutting Power

Feed per revolution fN = fz*Z [mm/rev] Pm - Motor Power (while not cutting)

3

Metal removal rate Q = ap*b*Vf [cm /min]

1000

L

w

Machining time Th = [min]

Vf

Specific cutting force Kc = Kc1*hm -mc Values for Motor Power PM

Max. Machine Power (kW) Motor Power Pm (kW)

Average chip thickness in hm ≈fz* [mm] 5.5 0.4

√

b

shoulder milling for b/D≤0.1 D 7.5 0.4-0.6

Average chip thickness in hm = ( sink 180 b fz ) [mm] 11.0 1.0

* *

*

15.0

1.5

shoulder milling for b/D>0.1 π D arcsin ( b/D) 18.0 2.2

* *

( a p b V f k c ) 22.0 2.5

* * *

Machining power P = 7 [kW]

*

*

6 10 h Motor Power Pm has a value of approximately

(1) See page 1006 7 to 12% of Maximum Machine Power

467

467