Page 293 - Iscar

P. 293

USER GUIDE

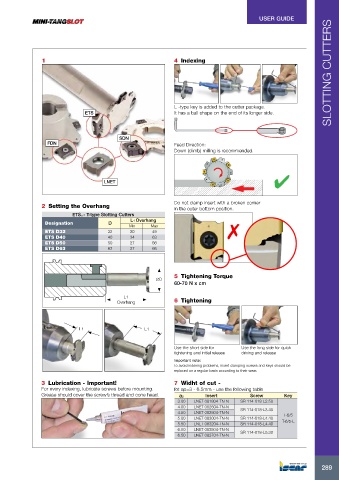

1 4 Indexing SLOTTING CUTTERS

L -type key is added to the cutter package.

ETS It has a ball shape on the end of its longer side.

SDN

FDN Feed Direction:

Down (climb) milling is recommended.

✔

LNET

Do not clamp insert with a broken corner

2 Setting the Overhang in the outer bottom position.

ETS..- T-type Slotting Cutters

L1 Overhang

Designation D

Min Max

ETS D32 32 20 49 ✗

ETS D40 40 34 63

ETS D50 50 27 66

ETS D63 63 27 66

5 Tightening Torque

∅D

60-70 N x cm

L1

Overhang 6 Tightening

L1 L1

Use the short side for Use the long side for quick

tightening and initial release driving and release

Important note:

To avoid indexing problems, insert clamping screws and keys should be

replaced on a regular basis according to their wear.

3 Lubrication - Important! 7 Widht of cut -

For every indexing, lubricate screws before mounting. fot ap=3 - 6.5mm - use the following table

Grease should cover the screw’s thread and cone head. ap Insert Screw Key

3.00 LNET 081804-TN-N SR 114-018-L2.50

4.00 LNET 082604-TN-N SR 114-018-L3.40

4.50 LNET 082804-TN-N T-6/5

5.00 LNET 083004-TN-N SR 114-018-L4.40 T-6/5-L

5.50 LNET 083204-TN-N SR 114-018-L4.40

6.00 LNET 083504-TN-N

6.50 LNET 083704-TN-N SR 114-018-L5.30

289

289