Page 70 - CAMFIX

P. 70

l

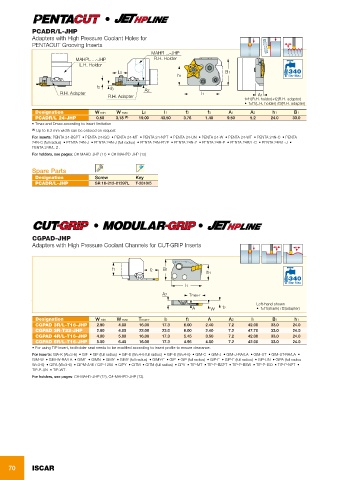

PCADR/L-JHP

Adapters with High Pressure Coolant Holes for

PENTACUT Grooving Inserts

MAHR ...-JHP

MAHPL ...-JHP R.H. Holder

L.H. Holder

L5 B1

h1 Bar Max

f2 f3

R.H. Adapter A2 l1

R.H. Adapter A1

f=f1(R.H. holder)+f2(R.H. adapter)

• f=f1(L.H. holder)+f3(R.H. adapter)

Designation W min W max L5 l1 f2 f3 A1 A2 h1 B1

PCADR/L 24-JHP 0.50 3.18 (1) 19.00 43.50 3.76 1.40 9.50 5.2 24.0 33.0

• Tmax and Dmax according to insert limitation

(1) Up to 6.2 mm width can be ordered on request

For inserts: PENTA 24-BSPT • PENTA 24-ISO • PENTA 24-MT • PENTA 24-NPT • PENTA 24-UN • PENTA 24-W • PENTA 24-WT • PENTA 24N-C • PENTA

24N-C (full radius) • PENTA 24N-J • PENTA 24N-J (full radius) • PENTA 24N-PF/P • PENTA 24N-Z • PENTA 24R-P • PENTA 24R/L-C • PENTA 24R/L-J •

PENTA 24R/L-Z .

For holders, see pages: C#-MAHD-JHP (11) • C#-MAHPD-JHP (13)

Spare Parts

Designation Screw Key

PCADR/L-JHP SR 16-212-01397L T-2010/5

l l

CGPAD-JHP

Adapters with High Pressure Coolant Channels for CUT-GRIP Inserts

f1 l2 B1

h1

Bar Max

l1

A2 Tmax-r

Left-hand shown

A W f2 • f=f1(shank)+f2(adapter)

Designation W min W max Tmax-r l2 f2 A A2 l1 B1 h1

CGPAD 3R/L-T16-JHP 2.80 4.00 16.00 17.3 6.00 2.40 7.2 42.00 33.0 24.0

CGPAD 3R-T22-JHP 2.80 4.00 22.00 23.0 6.00 2.40 7.2 47.70 33.0 24.0

CGPAD 4R/L-T16-JHP 4.00 5.00 16.00 17.3 5.45 3.50 7.2 42.00 33.0 24.0

CGPAD 5R/L-T16-JHP 5.00 6.40 16.00 17.3 4.95 4.50 7.2 42.00 33.0 24.0

• For using TIP insert, toolholder seat needs to be modified according to insert profile to ensure clearance.

For inserts: GIA-K (W=3-6) • GIF • GIF (full radius) • GIF-E (W=4-6 full radius) • GIF-E (W=4-6) • GIM-C • GIM-J • GIM-J-RA/LA • GIM-UT • GIM-UT-RA/LA •

GIM-W • GIM-W-RA/LA • GIMF • GIMN • GIMY • GIMY (full radius) • GIMY-F • GIP • GIP (full radius) • GIP-E • GIP-E (full radius) • GIP-UN • GIPA (full radius

W=3-6) • GIPA (W=3-6) • GIPM-A46 / GIP-1250 • GIPY • GITM • GITM (full radius) • GPV • TIP-MT • TIP-P-BSPT • TIP-P-BSW • TIP-P-ISO • TIP-P-NPT •

TIP-P-UN • TIP-WT .

For holders, see pages: C#-MAHD-JHP (12), C#-MAHPD-JHP (13).

70 ISCAR