Page 121 - CAMFIX

P. 121

l High Precision

Tools and Holders for

Quick Change

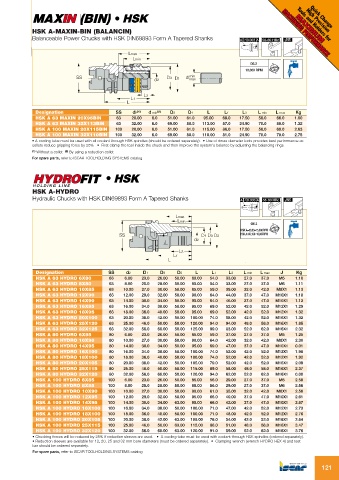

HSK A-MAXIN-BIN (BALANCIN) MACHINING PERFORMANCE

Balanceable Power Chucks with HSK DIN69893 Form A Tapered Shanks A 0.003 A 58-60 HRc √N5

MAXIMUM

Lmax

Lmin

G6.3

10,000 RPM

SS D3 D1 d min

d2 max

L3

L1

L

Designation SS d2 (1) d min (2) D3 D1 L L1 L3 L min L max Kg

HSK A 63 MAXIN 20X95BIN 63 20.00 6.0 51.00 61.0 95.00 69.0 17.50 56.0 66.0 1.00

HSK A 63 MAXIN 32X113BIN 63 32.00 6.0 69.00 80.0 113.00 87.0 24.90 70.0 85.0 1.32

HSK A 100 MAXIN 20X115BIN 100 20.00 6.0 51.00 61.0 115.00 86.0 17.50 56.0 69.0 2.63

HSK A 100 MAXIN 32X110BIN 100 32.00 6.0 69.00 80.0 110.00 81.0 24.90 70.0 78.0 2.75

• A cooling tube must be used with all coolant through HSK spindles (should be ordered separately). • Use of dmax diameter tools provides best performance as

collets reduce gripping force by 25% • First clamp the tool inside the chuck and then improve the system's balance by adjusting the balancing rings

(1) Without a collet (2) By using a reduction collet

For spare parts, refer to ISCAR TOOLHOLDING SYSTEMS catalog

l

HSK A-HYDRO

Hydraulic Chucks with HSK DIN69893 Form A Tapered Shanks A 0.003 A 58-60 HRc √N5

Lmax

Lmin

G6.3

HSK A=50,63=15,000RPM

SS D1 D3 D2 HSK A=80,100=10,000RPM

J d2

L3

L1

L .

Designation SS d2 D1 D3 D2 L L1 L3 L min L max J Kg

HSK A 63 HYDRO 6X80 63 6.00 23.0 26.00 50.00 80.00 54.0 33.00 27.0 37.0 M5 1.10

HSK A 63 HYDRO 8X80 63 8.00 25.0 28.00 50.00 80.00 54.0 33.00 27.0 37.0 M6 1.11

HSK A 63 HYDRO 10X85 63 10.00 27.0 30.00 50.00 85.00 59.0 39.00 32.0 42.0 M8X1 1.13

HSK A 63 HYDRO 12X90 63 12.00 29.0 32.00 50.00 90.00 64.0 44.00 37.0 47.0 M10X1 1.18

HSK A 63 HYDRO 14X90 63 14.00 30.0 34.00 50.00 90.00 64.0 46.00 37.0 47.0 M10X1 1.13

HSK A 63 HYDRO 16X95 63 16.00 34.0 38.00 50.00 95.00 69.0 52.00 42.0 52.0 M12X1 1.29

HSK A 63 HYDRO 18X95 63 18.00 36.0 40.00 50.00 95.00 69.0 52.00 42.0 52.0 M12X1 1.32

HSK A 63 HYDRO 20X100 63 20.00 38.0 42.00 50.00 100.00 74.0 58.00 42.0 52.0 M16X1 1.32

HSK A 63 HYDRO 25X120 63 25.00 46.0 50.00 50.00 120.00 94.0 94.00 48.0 58.0 M16X1 1.85

HSK A 63 HYDRO 32X125 63 32.00 56.0 60.00 50.00 125.00 99.0 83.00 52.0 62.0 M16X1 2.32

HSK A 80 HYDRO 6X85 80 6.00 23.0 26.00 50.00 85.00 59.0 37.00 27.0 37.0 M5 1.25

HSK A 80 HYDRO 10X90 80 10.00 27.0 30.00 50.00 90.00 64.0 42.00 32.0 42.0 M8X1 2.30

HSK A 80 HYDRO 14X95 80 14.00 30.0 34.00 50.00 95.00 69.0 47.00 37.0 47.0 M10X1 0.01

HSK A 80 HYDRO 16X100 80 16.00 34.0 38.00 50.00 100.00 74.0 52.00 42.0 52.0 M12X1 1.98

HSK A 80 HYDRO 18X100 80 18.00 36.0 40.00 50.00 100.00 74.0 52.00 42.0 52.0 M12X1 1.92

HSK A 80 HYDRO 20X105 80 20.00 38.0 42.00 50.00 105.00 79.0 52.00 42.0 52.0 M16X1 2.09

HSK A 80 HYDRO 25X115 80 25.00 46.0 50.00 50.00 115.00 89.0 58.00 48.0 58.0 M16X1 2.37

HSK A 80 HYDRO 32X120 80 32.00 56.0 60.00 50.00 120.00 94.0 62.00 52.0 62.0 M16X1 0.00

HSK A 100 HYDRO 6X85 100 6.00 23.0 26.00 50.00 85.00 56.0 29.00 27.0 37.0 M5 2.58

HSK A 100 HYDRO 8X85 100 8.00 25.0 28.00 50.00 85.00 56.0 29.00 27.0 37.0 M6 2.56

HSK A 100 HYDRO 10X90 100 10.00 27.0 30.00 50.00 90.00 61.0 35.00 32.0 42.0 M8X1 2.56

HSK A 100 HYDRO 12X95 100 12.00 29.0 32.00 50.00 95.00 66.0 40.00 37.0 47.0 M10X1 2.61

HSK A 100 HYDRO 14X95 100 14.00 30.0 34.00 63.00 95.00 66.0 42.00 37.0 47.0 M10X1 2.87

HSK A 100 HYDRO 16X100 100 16.00 34.0 38.00 50.00 100.00 71.0 47.00 42.0 52.0 M12X1 2.73

HSK A 100 HYDRO 18X100 100 18.00 36.0 40.00 50.00 100.00 71.0 48.00 42.0 52.0 M12X1 2.76

HSK A 100 HYDRO 20X105 100 20.00 38.0 42.00 63.00 105.00 76.0 54.00 42.0 52.0 M16X1 2.84

HSK A 100 HYDRO 25X115 100 25.00 46.0 50.00 63.00 115.00 86.0 51.00 48.0 58.0 M16X1 3.47

HSK A 100 HYDRO 32X120 100 32.00 56.0 60.00 63.00 120.00 91.0 59.00 52.0 62.0 M16X1 3.76

• Chucking forces will be reduced by 25% if reduction sleeves are used. • A cooling tube must be used with coolant through HSK spindles (ordered separately).

• Reduction sleeves are available for 12, 20, 25 and 32 mm bore diameters (must be ordered separately). • Clamping wrench (wrench HYDRO HEX 4) and test

bar should be ordered separately.

For spare parts, refer to ISCAR TOOLHOLDING SYSTEMS catalog

121