Page 216 - UNION

P. 216

part. Technical DaTa RECOMMENDATION OF CUTTING CONDITIONS MeMo

B

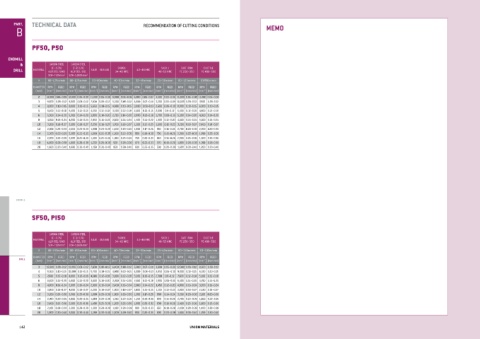

pF50, p50

endmill

& CARBON STEEL CARBON STEEL

(C < 0.3%)

SKD11

SKD61

(C ≧ 0.3%)

CAST IRON

DUCTILE

drill MATERIAL ALLOY STEEL / SS400 ALLOY STEEL / S50C SUJ2 · SUS440 34~43 HRC 43~48 HRC 48~53 HRC FC 250~350 FC 400~500

SCM~710N/mm 2 SCM~1,060N/mm 2

V 80~125m/min 80~125m/min 63~80m/min 40~63m/min 32~45m/min 25~36m/min 80~125m/min 63~90m/min

DIAMETER RPM FEED RPM FEED RPM FEED RPM FEED RPM FEED RPM FEED RPM FEED RPM FEED

(mm) (mm ) (mm/rev) (mm ) (mm/rev) (mm ) (mm/rev) (mm ) (mm/rev) (mm ) (mm/rev) (mm ) (mm/rev) (mm ) (mm/rev) (mm ) (mm/rev)

-1

-1

-1

-1

-1

-1

-1

-1

2 12,000 0.06~0.08 12,000 0.06~0.08 11,000 0.06~0.08 8,000 0.06~0.08 6,000 0.05~0.07 4,500 0.03~0.06 15,000 0.06~0.08 11,000 0.06~0.08

3 9,600 0.09~0.12 9,600 0.09~0.12 7,500 0.09~0.12 5,300 0.09~0.12 4,000 0.07~0.11 3,200 0.05~0.09 10,000 0.09~0.12 7,600 0.09~0.12

4 8,000 0.10~0.15 8,000 0.10~0.15 5,650 0.10~0.15 4,000 0.10~0.15 3,000 0.08~0.13 2,600 0.06~0.10 8,000 0.10~0.15 6,000 0.10~0.15

5 6,400 0.12~0.18 6,400 0.12~0.18 4,550 0.12~0.18 3,300 0.12~0.18 2,400 0.10~0.15 2,000 0.8~0.12 6,400 0.12~0.18 4,800 0.12~0.18

6 5,300 0.14~0.20 5,300 0.14~0.20 3,800 0.14~0.20 2,750 0.14~0.20 2,000 0.12~0.18 1,700 0.09~0.15 5,300 0.14~0.20 4,000 0.14~0.20

8 4,000 0.16~0.24 4,000 0.16~0.24 2,850 0.16~0.24 2,100 0.16~0.24 1,500 0.14~0.22 1,300 0.12~0.20 4,000 0.16~0.24 3,000 0.16~0.24

10 3,200 0.18~0.27 3,200 0.18~0.27 2,250 0.18~0.27 1,700 0.18~0.27 1,200 0.15~0.25 1,000 0.13~0.23 3,200 0.18~0.27 2,400 0.18~0.27

12 2,650 0.20~0.30 2,650 0.20~0.30 1,900 0.20~0.30 1,400 0.20~0.30 1,000 0.17~0.26 850 0.14~0.24 2,700 0.20~0.30 2,000 0.20~0.30

14 2,300 0.22~0.35 2,300 0.22~0.35 1,600 0.22~0.35 1,200 0.22~0.35 860 0.18~0.30 730 0.15~0.26 2,300 0.22~0.35 1,700 0.22~0.35

16 2,000 0.25~0.36 2,000 0.25~0.36 1,400 0.25~0.36 1,050 0.25~0.36 760 0.20~0.32 640 0.16~0.26 2,000 0.25~0.36 1,500 0.25~0.36

18 1,800 0.28~0.38 1,800 0.28~0.38 1,250 0.28~0.38 920 0.28~0.38 670 0.23~0.33 570 0.18~0.28 1,800 0.28~0.38 1,350 0.28~0.38

20 1,600 0.30~0.40 1,600 0.30~0.40 1,150 0.30~0.40 850 0.30~0.40 600 0.25~0.35 500 0.20~0.30 1,600 0.30~0.40 1,200 0.30~0.40

endmill

SF50, pi50

CARBON STEEL CARBON STEEL

(C < 0.3%) (C ≧ 0.3%) SKD61 SKD11 CAST IRON DUCTILE

MATERIAL SUJ2 · SUS440 43~48 HRC

ALLOY STEEL / SS400 ALLOY STEEL / S50C 34~43 HRC 48~53 HRC FC 250~350 FC 400~500

SCM~710N/mm 2 SCM~1,060N/mm 2

V 80~150m/min 80~150m/min 63~100m/min 40~70m/min 32~50m/min 25~40m/min 80~150m/min 63~100m/min

DIAMETER RPM FEED RPM FEED RPM FEED RPM FEED RPM FEED RPM FEED RPM FEED RPM FEED

drill -1 -1 -1 -1 -1 -1 -1 -1

(mm) (mm ) (mm/rev) (mm ) (mm/rev) (mm ) (mm/rev) (mm ) (mm/rev) (mm ) (mm/rev) (mm ) (mm/rev) (mm ) (mm/rev) (mm ) (mm/rev)

3 12,000 0.09~0.12 13,000 0.09~0.12 7,600 0.09~0.12 6,400 0.09~0.12 5,300 0.07~0.11 3,800 0.05~0.09 12,000 0.09~0.12 8,500 0.09~0.12

4 9,500 0.10~0.15 10,000 0.10~0.15 5,700 0.10~0.15 4,800 0.10~0.15 4,000 0.08~0.13 2,950 0.06~0.10 9,000 0.10~0.15 6,350 0.10~0.15

5 7,600 0.12~0.18 8,000 0.12~0.18 4,600 0.12~0.18 3,800 0.12~0.18 3,200 0.10~0.15 2,300 0.8~0.12 7,600 0.12~0.18 5,100 0.12~0.18

6 6,400 0.14~0.20 6,600 0.14~0.20 3,800 0.14~0.20 3,200 0.14~0.20 2,650 0.12~0.18 1,900 0.09~0.15 6,400 0.14~0.20 4,250 0.14~0.20

8 4,800 0.16~0.24 5,000 0.16~0.24 2,900 0.16~0.24 2,400 0.16~0.24 2,000 0.14~0.22 1,450 0.12~0.20 4,800 0.16~0.24 3,200 0.16~0.24

10 3,800 0.18~0.27 4,000 0.18~0.27 2,300 0.18~0.27 1,900 0.18~0.27 1,600 0.15~0.25 1,150 0.13~0.23 3,800 0.18~0.27 2,550 0.18~0.27

12 3,200 0.20~0.30 3,300 0.20~0.30 1,900 0.20~0.30 1,600 0.20~0.30 1,300 0.17~0.26 950 0.14~0.24 3,200 0.20~0.30 2,100 0.20~0.30

14 2,700 0.22~0.35 2,800 0.22~0.35 1,600 0.22~0.35 1,350 0.22~0.35 1,150 0.18~0.30 800 0.15~0.26 2,700 0.22~0.35 1,800 0.22~0.35

16 2,400 0.25~0.36 2,500 0.25~0.36 1,400 0.25~0.36 1,200 0.25~0.36 1,000 0.20~0.32 700 0.16~0.26 2,400 0.25~0.36 1,600 0.25~0.36

18 2,100 0.28~0.38 2,200 0.28~0.38 1,300 0.28~0.38 1,100 0.28~0.38 900 0.23~0.33 650 0.18~0.28 2,100 0.28~0.38 1,400 0.28~0.38

20 1,900 0.30~0.40 2,000 0.30~0.40 1,150 0.30~0.40 1,000 0.30~0.40 800 0.25~0.35 600 0.20~0.30 1,900 0.30~0.40 1,250 0.30~0.40

142 Union Materials